The accuracy of laser welding can be as precise as 0.1mm from the edge of the welding wire to the flow channel, which is no vibration, noise, or dust during the welding process, making it an ideal choice for the precision welding requirements of medical plastic products. And laser chiller is needed to accurately control the laser's temperature to ensure the stability of the laser beam output.

Microfluidics was developed in the 1980s and refers to a technology for precise control and manipulation of micro-scale fluids, especially submicron structures. It is an interdisciplinary technology involving chemistry, fluid physics, microelectronics, new materials, biology, and biomedical engineering. Thanks to its small volume, low energy consumption, and small device footprint, microfluidics is highly promising for a variety of applications in medical diagnosis, biochemical analysis, chemical synthesis, and environmental monitoring.

The mainstream form of microfluidic chips refers to the basic integration of operating units involved in the fields of chemistry and biology such as sample preparation, reaction, separation, detection, cell culture, sorting, and lysis into a piece of several square centimeters or even on a smaller chip. A network of microchannels is formed, and a controllable fluid runs through the entire system. Microfluidic chips have several advantages such as light volume, less sample and reagent volume, fast reaction speed, large-scale parallel processing, and disposability in the fields of biology, chemistry, medicine, etc.

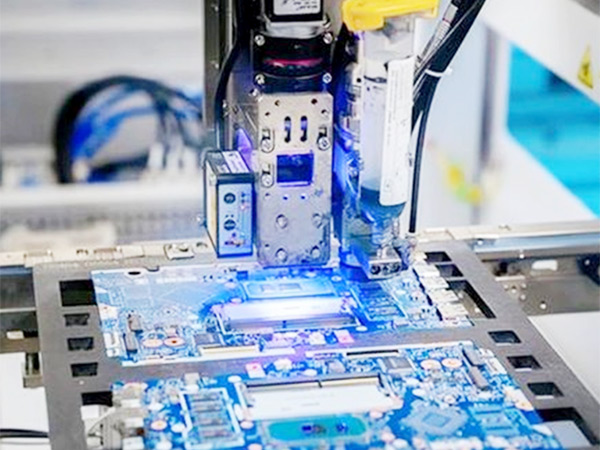

Precision Laser Welding Enhances Microfluidic Chip

A microfluidic chip is a small plastic-based chip that integrates multiple steps, including sample preparation, biochemical reactions, and result detection. However, to convert the number of reagents into microliters or even nanoliters or picoliters, the welding technology requirements are extremely high.

Common welding techniques like ultrasonic, heat pressing, and gluing have drawbacks. Ultrasonic technology is prone to spillage and dust, while hot pressing technology can easily deform and overflow, resulting in low production efficiency.

Laser welding, on the other hand, is a non-contact welding technique that uses a thin laser beam to connect parts with extreme precision and speed. This method does not impact the flow channel, and welding accuracy can be as precise as 0.1mm from the edge of the welding wire to the flow channel. There is no vibration, noise, or dust during the welding process. Such a clean welding method makes it an ideal choice for the precision welding requirements of medical plastic products.

Laser Welding Must Be Equipped With a Laser Chiller

For microfluidic chip precision processing, the laser welding machine needs to accurately control the laser's temperature to ensure the stability of the laser beam output. Thus a laser welding chiller is necessary. TEYU laser chiller manufacturer has over 21 years of laser cooling experience, with more than 90 products applicable to over 100 industries. For instance, CWFL series chillers provide a dual temperature control mode for cooling the laser and the optics separately. Multiple alarm warnings, and Modbus-485 functions, provide strong support for the fine processing of laser welding.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.