Точність лазерного зварювання може сягати 0,1 мм від краю зварювального дроту до каналу потоку, що не призводить до вібрації, шуму чи пилу під час процесу зварювання, що робить його ідеальним вибором для вимог до прецизійного зварювання медичних пластмасових виробів. А лазерний охолоджувач необхідний для точного контролю температури лазера, щоб забезпечити стабільність вихідного лазерного променя.

Чи потрібен лазерний охолоджувач для мікрофлюїдного лазерного зварювання?

Мікрофлюїдика була розроблена в 1980-х роках і стосується технології точного контролю та маніпулювання мікромасштабними рідинами, особливо субмікронними структурами. Це міждисциплінарна технологія, що охоплює хімію, фізику рідин, мікроелектроніку, нові матеріали, біологію та біомедичну інженерію. Завдяки малому об'єму, низькому споживанню енергії та компактним розмірам пристрою, мікрофлюїдика є дуже перспективною для різноманітних застосувань у медичній діагностиці, біохімічному аналізі, хімічному синтезі та моніторингу навколишнього середовища.

Основна форма мікрофлюїдних чіпів стосується базової інтеграції операційних блоків, що використовуються в галузях хімії та біології, таких як підготовка зразків, реакція, розділення, детекція, культивування клітин, сортування та лізис, на фрагменті розміром кілька квадратних сантиметрів або навіть на меншому чіпі. Формується мережа мікроканалів, і керована рідина протікає через всю систему. Мікрофлюїдні чіпи мають ряд переваг, таких як малий об'єм, менший об'єм зразка та реагенту, висока швидкість реакції, великомасштабна паралельна обробка та одноразовість у галузях біології, хімії, медицини тощо.

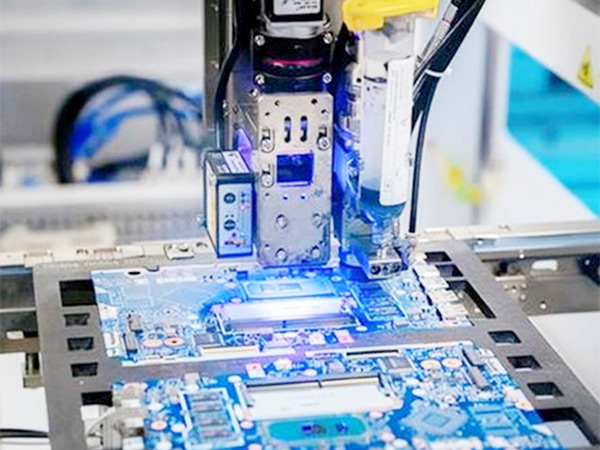

Прецизійне лазерне зварювання покращує мікрофлюїдний чіп

Мікрофлюїдний чіп — це невеликий чіп на пластиковій основі, який об'єднує кілька етапів, включаючи підготовку зразків, біохімічні реакції та визначення результатів. Однак, щоб перевести кількість реагентів у мікролітри, або навіть нанолітри, або піколітри, вимоги до технології зварювання надзвичайно високі.

Звичайні методи зварювання, такі як ультразвукове, гаряче пресування та склеювання, мають недоліки. Ультразвукова технологія схильна до розсипання та пилу, тоді як технологія гарячого пресування може легко деформуватися та переливатися, що призводить до низької ефективності виробництва.

Лазерне зварювання, з іншого боку, – це безконтактний метод зварювання, який використовує тонкий лазерний промінь для з'єднання деталей з надзвичайною точністю та швидкістю. Цей метод не впливає на канал потоку, а точність зварювання може сягати 0,1 мм від краю зварювального дроту до каналу потоку. Під час процесу зварювання немає вібрації, шуму чи пилу. Такий чистий метод зварювання робить його ідеальним вибором для вимог до прецизійного зварювання медичних пластмасових виробів.

Лазерне зварювання повинно бути оснащене лазерним чилером

Для прецизійної обробки мікрофлюїдних чіпів лазерний зварювальний апарат повинен точно контролювати температуру лазера, щоб забезпечити стабільність лазерного променя. Тому необхідний чилер для лазерного зварювання . Виробник лазерних чилерів TEYU має понад 21 рік досвіду в лазерному охолодженні, пропонуючи понад 90 продуктів, що застосовуються в понад 100 галузях промисловості. Наприклад, чилери серії CWFL забезпечують подвійний режим контролю температури для окремого охолодження лазера та оптики. Кілька попереджень про тривогу та функції Modbus-485 забезпечують потужну підтримку для точної обробки лазерного зварювання.

Ми поруч, коли вам це потрібно.

Будь ласка, заповніть форму, щоб зв'язатися з нами, і ми будемо раді вам допомогти.