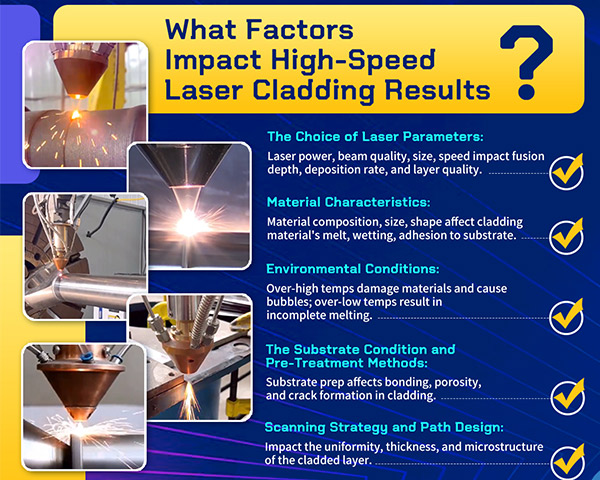

What factors affect the results of high-speed laser cladding? The main impact factors are laser parameters, material characteristics, environmental conditions, substrate condition and pre-treatment methods, scanning strategy and path design. For over 22 years, TEYU Chiller Manufacturer has focused on industrial laser cooling, delivering chillers ranging from 0.3kW to 42kW to cater to diverse laser cladding equipment cooling needs.

High-speed laser cladding has emerged as a transformative method in material processing, enhancing the efficiency and precision of surface modification and material deposition. Do you know what factors impact high-speed laser cladding results? Let's explore:

1. Laser Parameters. Variables such as laser power, beam quality, spot size, and scanning speed dictate the depth of fusion, material deposition rate, and overall quality of the cladded layer. Optimal parameter selection is crucial to achieve desired surface properties while ensuring minimal thermal distortion.

2. Material Characteristics: the composition, particle size, and morphology of the laser cladding material profoundly influence its meltability, wettability, and adhesion to the substrate. Compatibility between the substrate and cladding material is essential for achieving superior bonding.

3. Environmental Conditions: ambient temperature, humidity, and gas environment during the cladding process are critical. For example, over-high temperatures can damage materials, cause bubbles, and disrupt structures, while over-low temperatures lead to incomplete melting, solidification issues, and poor adhesion, affecting laser cladding quality. To address temperature control in laser cladding, a laser chiller unit is commonly used.

4. The Substrate Condition and Pre-Treatment Methods. Surface roughness, cleanliness, and preheating of the substrate influence the bonding strength, porosity, and crack formation in the cladded layer. Adequate preparation of the substrate surface is essential to optimize the adhesion and integrity of the cladding.

5. Scanning Strategy and Path Design: greatly influence the uniformity, thickness, and microstructure of the cladded layer. Precision in controlling the laser beam movement and overlapping tracks ensures consistent deposition and desired mechanical properties.

For over 22 years, TEYU Chiller Manufacturer has focused on industrial laser cooling, delivering chillers ranging from 0.3kW to 42kW to cater to diverse laser cladding equipment cooling needs. If you're interested, just feel free to learn more at Fiber Laser Chiller, or direct send an email to [email protected] to get your exclusive cooling solution.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.