Laser chillers are essential for ensuring wafer dicing quality in semiconductor manufacturing. By managing temperature and minimizing thermal stress, they help reduce burrs, chipping, and surface irregularities. Reliable cooling enhances laser stability and extends equipment life, contributing to higher chip yield.

Wafers are the foundational material in semiconductor manufacturing, serving as substrates for integrated circuits and other microelectronic devices. Typically made from monocrystalline silicon, wafers are smooth, flat, and usually 0.5 mm thick, with common diameters of 200 mm (8 inches) or 300 mm (12 inches). The production process is highly complex, involving silicon purification, ingot slicing, wafer polishing, photolithography, etching, ion implantation, electroplating, wafer testing, and finally, wafer dicing. Due to their material properties, wafers demand strict control over purity, flatness, and defect rates, as these directly impact chip performance.

Common Wafer Dicing Challenges

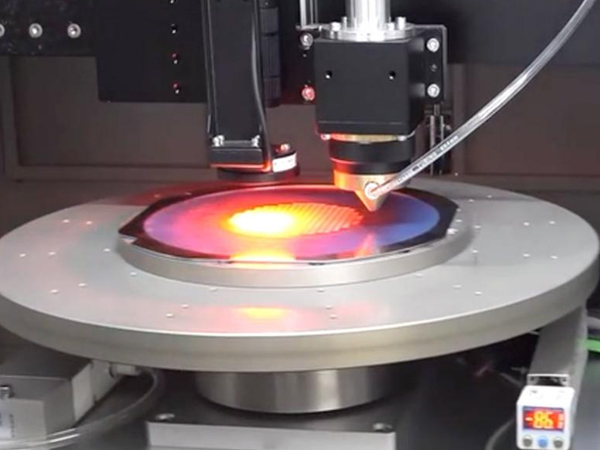

Laser dicing technology is widely adopted in wafer processing due to its high precision and non-contact advantages. However, several quality issues may arise during dicing:

Burrs and Chipping: These defects often result from inadequate cooling or worn cutting tools. Enhancing the cooling system by upgrading the chiller capacity and increasing water flow can help reduce uneven heating and minimize edge damage.

Reduced Cutting Accuracy: Caused by poor machine positioning, unstable worktables, or incorrect cutting parameters. Accuracy can be restored by improving machine calibration and optimizing parameter settings.

Uneven Cut Surfaces: Blade wear, improper settings, or spindle misalignment can lead to surface irregularities. Regular maintenance and machine recalibration are essential to ensure a smooth cut.

Role of Laser Chillers in Wafer Dicing

Laser chillers play a vital role in maintaining the performance and stability of laser and optical systems used in wafer dicing. By delivering precise temperature control, they prevent laser wavelength drift caused by temperature fluctuations, which is critical for maintaining cutting accuracy. Effective cooling also minimizes thermal stress during dicing, reducing the risk of lattice distortion, chipping, or microcracks that can compromise wafer quality.

In addition, laser chillers use a closed-loop water cooling system that isolates the cooling circuit from external contamination. With integrated monitoring and alarm systems, they significantly enhance the long-term reliability of wafer dicing equipment.

As wafer dicing quality directly impacts chip yield, incorporating a reliable laser chiller helps minimize common defects and maintain consistent performance. Selecting the appropriate chiller based on the laser system's thermal load and operating environment, along with regular maintenance, is key to ensuring stable and efficient operation.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.