Metal laser 3D printing offers higher design freedom, improved production efficiency, greater material utilization, and strong customization capabilities compared to traditional methods. TEYU laser chillers ensure consistent performance and longevity of 3D printing systems by providing reliable thermal management solutions tailored to laser equipment.

Metal laser 3D printing, as an emerging manufacturing technology, offers significant advancements over traditional metal processing methods. From enhanced design freedom and production efficiency to superior material utilization and cost-effectiveness, metal laser 3D printing also provides unmatched flexibility for customization. Below, we analyze the key advantages of this innovative technology:

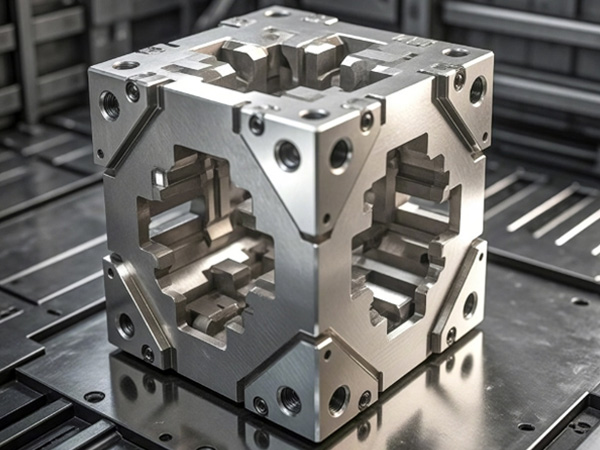

Higher Design Freedom: Metal laser 3D printing enables the creation of complex shapes and structures that are difficult or impossible to achieve with traditional methods. This capability provides designers with greater creative flexibility and opens new possibilities in product development.

Improved Production Efficiency: By directly converting digital models into physical objects, metal laser 3D printing significantly shortens the cycle from design to finished product. It simplifies the production process and reduces the number of manufacturing steps required.

Greater Material Utilization: Unlike traditional methods that often involve significant material waste, metal laser 3D printing precisely uses the required amount of material. This minimizes waste and maximizes resource efficiency, making it an environmentally friendly option.

Cost-Effective Solutions: Metal laser 3D printing reduces development costs by optimizing product designs and minimizing production steps. It is particularly well-suited for small-batch manufacturing and prototype creation, offering cost savings compared to traditional methods.

Strong Customization Capabilities: This technology allows for personalized customization based on customer needs. Designs can be quickly adjusted to produce unique, tailored products without the need for extensive retooling.

The Essential Role of Laser Chillers in Metal Laser 3D Printing

Laser chillers play a critical role in ensuring the success of metal laser 3D printing processes. During printing, the laser generates significant heat, which, if not efficiently dissipated, can lead to decreased performance or damage to the laser system. Laser chillers provide effective thermal management by circulating cooling water to remove excess heat, maintaining a stable operating temperature for the laser. This ensures consistent print quality and prolongs the lifespan of the laser equipment.

TEYU Laser Chillers: Trusted Cooling Solutions for Metal 3D Printer

With 23 years of experience in laser cooling technology, TEYU Chiller Manufacturer offers 100+ standard models of laser chillers tailored to meet the cooling requirements of various laser systems. Our reliable and efficient cooling solutions are designed to optimize the performance and longevity of metal laser 3D printing systems, ensuring uninterrupted operation and exceptional results.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.