The need for a water chiller in your 80W-130W CO2 laser cutter engraver setup depends on various factors, including power rating, operating environment, usage patterns, and material requirements. Water chillers offer significant performance, lifespan, and safety benefits. It's essential to assess your specific requirements and budget constraints to determine how to invest in a suitable water chiller for your CO2 laser cutter engraver.

Investing in a CO2 laser cutter engraver can significantly boost productivity and creativity in various industries, from crafting and prototyping to industrial manufacturing. However, with power ranging from 80W to 130W, these machines generate substantial heat during operation, necessitating proper cooling mechanisms. One commonly debated component is the water chiller. In this article, we delve into whether a water chiller is necessary for your 80W-130W CO2 laser cutter engraver setup.

Understanding CO2 Laser Systems:

Before delving into the necessity of a water chiller, it's crucial to understand how CO2 laser cutter engravers operate. These systems utilize high-powered CO2 lasers to cut or engrave various materials such as wood, acrylic, leather, and more. The laser beam's intensity generates heat, which, if not effectively managed, can lead to performance issues, material damage, or even equipment failure.

Heat Management in Laser Systems:

Effective heat management is essential for maintaining optimal performance and prolonging the lifespan of your CO2 laser cutter engraver. Without proper cooling, excessive heat can degrade laser tube performance, reduce cutting and engraving quality, and increase the risk of overheating-related failures.

The Role of Water Chillers:

Water chillers are commonly used in CO2 laser systems to regulate the temperature of the laser tube and other critical components. These devices circulate chilled water through the laser tube to dissipate heat generated during operation, effectively maintaining a stable operating temperature.

Factors Influencing the Need for a Water Chiller:

Several factors influence whether a water chiller is necessary for your 80W-130W CO2 laser cutter engraver setup: (1)Power Rating: Higher-powered laser systems, such as those rated between 80W and 130W, generate more heat during operation. As a result, they typically require more robust cooling solutions to maintain optimal performance. (2)Ambient Temperature: Operating environment temperature plays a significant role in determining cooling requirements. In warmer climates or poorly ventilated spaces, ambient heat can exacerbate thermal management challenges, making water chillers more essential. (3)Continuous Operation: If you plan to use your CO2 laser cutter engraver for prolonged periods or engage in high-volume production runs, a water chiller becomes increasingly necessary to prevent overheating and ensure consistent performance. (4)Material Compatibility: Certain materials, such as metals or thick acrylics, may require higher laser power settings, resulting in increased heat generation. Using a water chiller can help offset the thermal effects of processing such materials, maintaining precision and quality.

Benefits of Using a Water Chiller:

Incorporating a water chiller into your CO2 laser system offers several benefits: (1)Enhanced Performance: A water chiller ensures consistent laser power output and cutting/engraving quality by maintaining optimal operating temperatures. (2)Extended Equipment Lifespan: Proper thermal management reduces stress on critical components, prolonging the lifespan of the laser tube and other system parts. (3)Improved Safety: Effective cooling minimizes the risk of overheating-related accidents or equipment failures, enhancing workplace safety. (4)Reduced Maintenance: By mitigating heat-related issues, water chillers help minimize downtime and reduce the frequency of maintenance and repairs.

How to Choose a Suitable CO2 Laser Cutter Engraver Chiller?

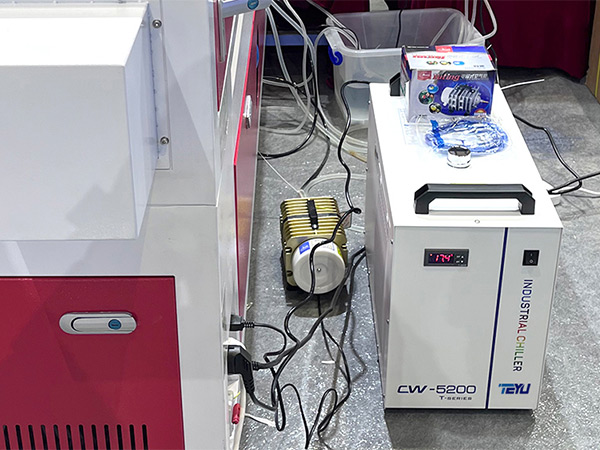

When considering a water chiller for your 80W-130W CO2 laser cutter engraver, it's important to choose one that is compatible with your specific machine and its power requirements after assessing your specific requirements and budget constraints. As a water chiller maker and chiller supplier with 22 years of experience, TEYU Chiller offers a variety of water chiller products, including a complete line of CO2 Laser Chillers. The water chiller CW-5200 is one of the best-selling chiller models. It has a small size, a temperature control accuracy of ±0.3°C, and an 890W large cooling capacity. CO2 laser chiller CW-5200 provides stable and efficient cooling for 80W-130W CO2 laser cutters engravers, meeting various CO2 laser brands' cooling needs on the market. If you're looking for an 80W-130W CO2 laser cutter engraver chiller, TEYU water chiller CW-5200 would be your ideal choice.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.