Whether for intricate crafts or fast commercial advertising production, laser engravers are highly efficient tools for detailed work on various materials. They are extensively used in industries such as crafts, woodworking, and advertising. What should you consider when purchasing a laser engraving machine? You should identify industry needs, assess equipment quality, choose appropriate cooling equipment (water chiller), train and learn for operation, and regular maintenance and care.

Laser engraving machines hold a significant place in modern manufacturing due to their excellent processing capabilities and wide range of applications. Whether for intricate crafts or fast commercial advertising production, they are highly efficient tools for detailed work on various materials. They are extensively used in industries such as crafts, woodworking, and advertising. So, what should you consider when purchasing a laser engraving machine?

1. Identify Industry Needs

Before purchasing a laser engraving machine, you need to determine the specifications and functions based on the specific needs of your industry:

Craft Manufacturing: Choose a machine capable of fine engraving.

Woodworking Industry: Consider high-power machines to handle hardwood processing.

Advertising Industry: Look for machines that can quickly process various materials.

2. Assess Equipment Quality

The quality of the laser engraving machine directly affects the quality of the finished product and the machine's lifespan. Key factors to assess include:

Durability: Opt for machines made from durable materials.

Precision: High-precision machines offer more detailed engraving results.

Brand Reputation: Select brands with high recognition and positive user reviews.

After-Sales Service: Good after-sales service provides effective support when issues arise.

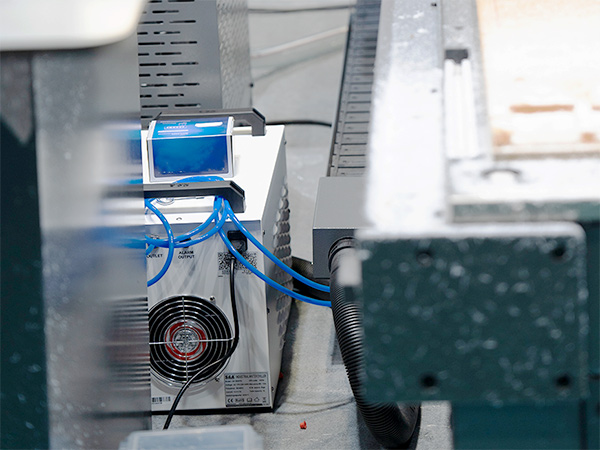

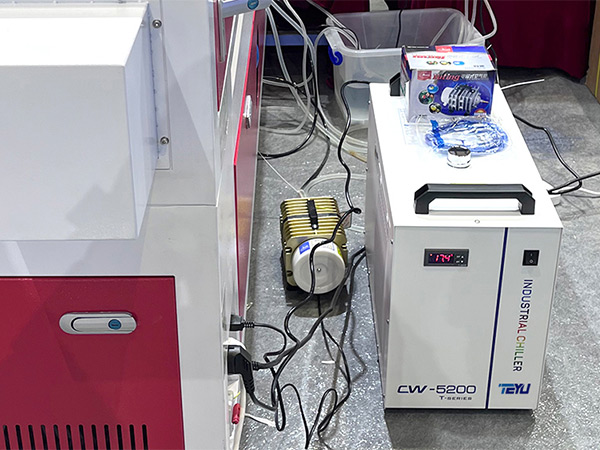

3. Choose Appropriate Cooling Equipment

Laser engraving machines generate heat during operation, so appropriate cooling equipment is essential:

Water Chiller: Select a water chiller that matches the cooling capacity required by the laser engraving machine.

TEYU Water Chiller: With 22 years of experience in industrial laser cooling, TEYU Water Chiller Manufacturer’s annual shipment reaches 160,000 units, sold in over 100 countries and regions. We offer numerous laser engraving chiller application cases, effectively enhancing laser engraving equipment efficiency and extending the lifespan of the machine.

4. Training and Learning for Operation

To use the laser engraving machine safely and efficiently, operators need proper training:

User Manual: Familiarize yourself with the user manual to understand all functions and operational steps.

Training Courses: Attend manufacturer-provided training courses or watch online tutorials.

Software Learning: Learn how to use the Computer-Aided Manufacturing (CAM) software.

5. Regular Maintenance and Care

Regular maintenance is crucial for maintaining the performance of the laser engraving machine:

Cleaning: Regularly clean the machine, especially the laser head and work surface.

Lubrication: Periodically lubricate moving parts to reduce wear and tear.

Inspection: Check all machine components to ensure they are functioning properly.

Software Updates: Keep the control software updated to the latest version.

By thoroughly considering the above factors, you can choose the right laser engraving machine. Pairing it with an efficient TEYU water chiller will not only boost your engraving work efficiency but also ensure the long-term stable operation of the laser engraving machine.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.