With the rapid advancement of technology, laser cutting has become widely used in manufacturing, design, and cultural creation industries due to its high precision, efficiency, and high yield of finished products. TEYU Chiller Maker and Chiller Supplier, has specialized in laser chillers for over 22 years, offering 120+ chiller models to cool various types of laser cutting machines.

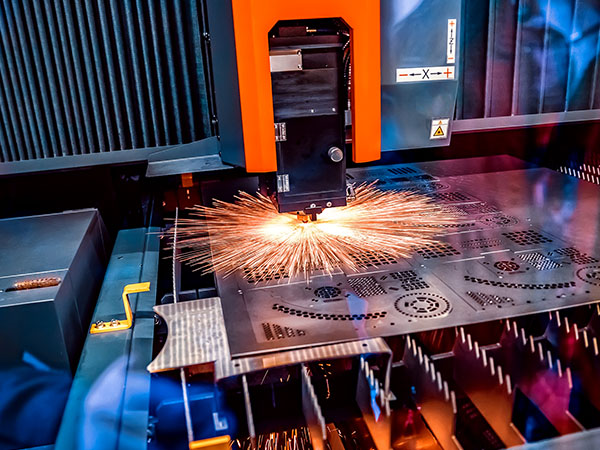

With the rapid advancement of technology, laser cutting has become widely used in manufacturing, design, and cultural creation industries due to its high precision, efficiency, and high yield of finished products. Despite being a high-tech processing method, not all materials are suitable for laser cutting. Let's discuss which materials are suitable and which are not.

Materials Suitable for Laser Cutting

Metals: Laser cutting is particularly suitable for the precision machining of metals, including but not limited to medium carbon steel, stainless steel, aluminum alloys, copper alloys, titanium, and carbon steel. The thickness of these metal materials can range from a few millimeters to several dozen millimeters.

Wood: Rosewoods, softwoods, engineered wood, and medium-density fiberboard (MDF) can be finely processed using laser cutting. This is commonly applied in furniture manufacturing, model design, and artistic creation.

Cardboard: Laser cutting can create intricate patterns and designs, often used in the production of invitations and packaging labels.

Plastics: Transparent plastics like acrylic, PMMA, and Lucite, as well as thermoplastics such as polyoxymethylene, are suitable for laser cutting, allowing for precise processing while maintaining material properties.

Glass: Although glass is fragile, laser cutting technology can cut it effectively, making it suitable for producing instruments and special decorative items.

Materials Unsuitable for Laser Cutting

PVC (Polyvinyl Chloride): Laser cutting PVC releases toxic hydrogen chloride gas, which is hazardous to both operators and the environment.

Polycarbonate: This material tends to discolor during laser cutting, and thicker materials cannot be cut effectively, compromising the quality of the cut.

ABS and Polyethylene Plastics: These materials tend to melt rather than vaporize during laser cutting, leading to irregular edges and affecting the appearance and properties of the final product.

Polyethylene and Polypropylene Foam: These materials are flammable and pose safety risks during laser cutting.

Fiberglass: Because it contains resins that produce harmful fumes when cut, fiberglass is not ideal for laser cutting due to its adverse effects on the working environment and equipment maintenance.

Why Are Some Materials Suitable or Unsuitable?

The suitability of materials for laser cutting mainly depends on their absorption rate of laser energy, thermal conductivity, and the chemical reactions during the cutting process. Metals are ideal for laser cutting due to their excellent thermal conductivity and lower laser energy transmittance. Wood and paper materials also yield better cutting results due to their combustibility and absorption of laser energy. Plastics and glass have specific physical properties that make them suitable for laser cutting under certain conditions.

Conversely, some materials are unsuitable for laser cutting because they may produce harmful substances during the process, tend to melt rather than vaporize, or cannot effectively absorb laser energy due to high transmittance.

The Necessity of Laser Cutting Chillers

In addition to considering material suitability, it is essential to manage the heat generated during laser cutting. Even suitable materials require careful control of thermal effects during the cutting process. To maintain consistent and stable temperatures, laser cutting machines need laser chillers to provide reliable cooling, ensure smooth operation, extend the lifespan of laser equipment, and enhance production efficiency.

TEYU Chiller Maker and Chiller Supplier, has specialized in laser chillers for over 22 years, offering over 120 chiller models for cooling CO2 laser cutters, fiber laser cutters, YAG laser cutters, CNC cutters, ultrafast laser cutters, etc. With an annual shipment of 160,000 chiller units and exports to over 100 countries, TEYU Chiller is a trusted partner for many laser enterprises.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.