Thanks to its vast manufacturing industry, China has a massive market for laser applications. Laser technology will help traditional Chinese enterprises undergo transformation and upgrading, driving industrial automation, efficiency, and environmental sustainability. As a leading water chiller manufacturer with 22 years of experience, TEYU provides cooling solutions for laser cutters, welders, markers, printers...

Laser processing technology has been developing in China for over 20 years, thanks to the vast manufacturing sector, which offers a huge market for its application. Over this time, China's industrial laser industry has grown from scratch and the price of industrial laser equipment has dropped significantly, making it more affordable and accessible to a broader range of users. This is a key reason for the rapid adoption and scaling of laser equipment in China.

Traditional Industries Need Laser Technology More Than High-Tech Sectors Do

Laser processing is a cutting-edge manufacturing method. While its applications in biomedical, aerospace, and new energy are often highlighted, it is in traditional industries where laser technology is most widely used. These conventional sectors were the earliest to generate large-scale demand for laser equipment.

These industries already have well-established production methods and processes, so the development and promotion of laser equipment represent a continuous process of product and technological upgrades. The growth of the laser market comes from uncovering new, niche applications.

Today, the emergence of new technological concepts and industries doesn’t mean that traditional industries are outdated or destined for obsolescence. Quite the opposite—many traditional sectors, such as clothing and food, remain essential to daily life. Instead of being eliminated, they need to undergo transformation and upgrades to develop more healthily and become more technologically advanced. Laser technology serves as a crucial driving force in this transformation, providing traditional industries with new momentum.

Laser Cutting Plays a Key Role in Metal Cutting

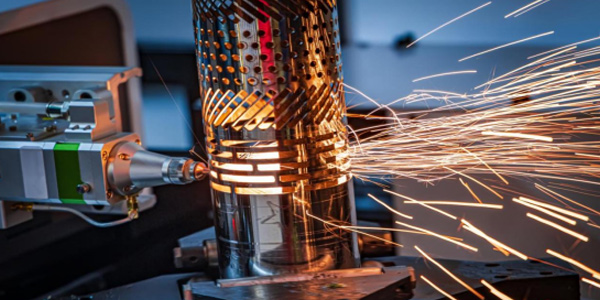

Metal pipes are widely used in daily life, particularly in sectors such as furniture, construction, gas, bathrooms, windows and doors, and plumbing, where there is a high demand for pipe cutting. In the past, cutting pipes was done with abrasive wheels, which, though cheap, were relatively primitive. The wheels wore out quickly, and the precision and smoothness of the cuts left much to be desired. Cutting a section of pipe with an abrasive wheel used to take 15-20 seconds, whereas laser cutting takes just 1.5 seconds, improving production efficiency by over ten times. Additionally, laser cutting does not require consumable materials, operates at a high level of automation, and can work continuously, whereas abrasive cutting requires manual operation. In terms of cost-effectiveness, laser cutting is superior. This is why laser pipe cutting quickly replaced abrasive cutting, and today, laser pipe cutting machines are widely used across all pipe-related industries. The TEYU CWFL series water chiller, with dual cooling channels, is ideal for metal laser cutting equipment.

TEYU laser chiller CWFL-1000 for cooling laser tube cutting machine

Laser Technology Addresses Pain Points in the Apparel Industry

Clothing, as a daily necessity, is produced in the billions each year. Yet, the application of lasers in the apparel industry often goes unnoticed, largely because this field is dominated by CO2 lasers. Traditionally, fabric cutting has been done using cutting tables and tools. However, CO2 laser cutting systems provide a fully automated and highly efficient processing solution. Once the design is programmed into the system, it only takes a few seconds to cut and shape a piece of clothing, with minimal waste, thread debris, or noise—making it highly popular in the garment industry. Efficient, energy-saving, and easy to use, TEYU CW series water chillers are ideal for CO2 laser processing equipment.

TEYU water chiller CW-5000 for cooling textile co2 laser cutting machines 80W

One major challenge in the apparel sector is related to dyeing. Lasers can engrave designs or text directly onto garments, producing patterns in white, gray, and black without the need for traditional dyeing processes. This significantly reduces wastewater pollution. For instance, in the denim industry, the washing process has historically been a major source of wastewater pollution. The advent of laser washing has breathed new life into denim production. Without the need for soaking, lasers can achieve the same washing effect with just a quick scan. Lasers can even create hollowed-out and engraved designs. Laser technology has effectively resolved the environmental challenges of denim production and has become widely embraced by the denim industry.

Laser Marking: The New Standard in the Packaging Industry

Laser marking has become the standard for the packaging industry, which includes paper materials, plastic bags/bottles, aluminum cans, and tin boxes. Most products require packaging before they can be sold, and by regulation, packaged goods must display production dates, origins, barcodes, and other information. Traditionally, ink screen printing was used for these markings. However, ink carries a distinct odor and poses environmental hazards, especially in the case of food packaging, where ink poses potential safety risks. The emergence of laser marking and laser coding has largely replaced ink-based methods. Today, if you take a close look, you'll notice that laser marking is used on bottled water, pharmaceuticals, aluminum cans of beer, plastic packaging, and more, with ink printing becoming rare. Automated laser marking systems, designed for high-volume production lines, now play a critical role in the packaging industry. Space-saving, efficient, and easy to use, TEYU CWUL series water chillers are ideal for laser marking equipment.

TEYU water chiller CWUL-05 for cooling UV laser marking machines 3W-5W

China has a vast number of traditional industries with significant potential for laser applications. The next wave of growth for laser processing lies in replacing traditional manufacturing methods, and these industries will need laser technology to assist in their transformation and upgrade. This creates a mutually beneficial relationship and presents an important avenue for the differentiated development of the laser industry.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.