Heater

Water Filter

US standard plug / EN standard plug

Precision Temperature Control Solutions for 3D Printers

Model: CW-6200

Machine Size: 67X47X89cm (L X W X H)

Warranty: 2 years

Standard: CE, REACH and RoHS

| Model | CW-6200ANTY | CW-6200BNTY |

| Voltage | AC 1P 220-240V | AC 1P 220-240V |

| Frequency | 50Hz | 60Hz |

| Current | 2.3~9.5A | 2.1~10.1A |

Max. power consumption | 1.91kW | 1.88kW |

| Compressor power | 1.41kW | 1.62kW |

| 1.89HP | 2.17HP | |

| Nominal cooling capacity | 17401Btu/h | |

| 5.1kW | ||

| 4384Kcal/h | ||

| Pump power | 0.37kW | |

Max. pump pressure | 2.7bar | |

Max. pump flow | 75L/min | |

| Refrigerant | R-410A | |

| Precision | ±0.5℃ | |

| Reducer | Capillary | |

| Tank capacity | 22L | |

| Inlet and outlet | Rp1/2" | |

| N.W. | 57Kg | 59Kg |

| G.W. | 68Kg | 70Kg |

| Dimension | 67X47X89cm (L X W X H) | |

| Package dimension | 73X57X105cm (L X W X H) | |

The working current can be different under different working conditions. The above information is for reference only. Please subject to the actual delivered product.

* Precise Temperature Control: Maintains stable and accurate cooling to prevent overheating, ensuring consistent print quality and equipment stability.

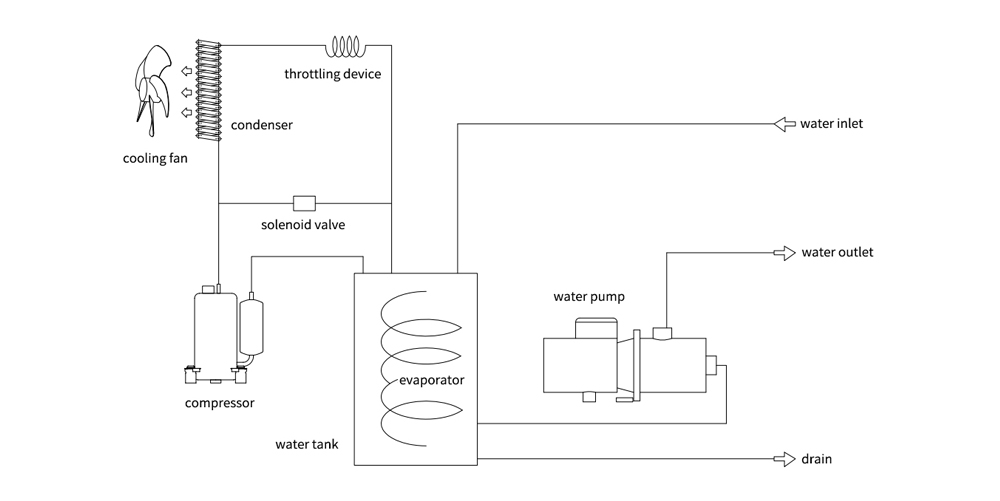

* Efficient Cooling System: High-performance compressors and heat exchangers effectively dissipate heat, even during long print jobs or high-temperature applications.

* Real-Time Monitoring & Alarms: Equipped with an intuitive display for real-time monitoring and system fault alarms, ensuring smooth operation.

* Energy-Efficient: Designed with energy-saving components to reduce power consumption without sacrificing cooling efficiency.

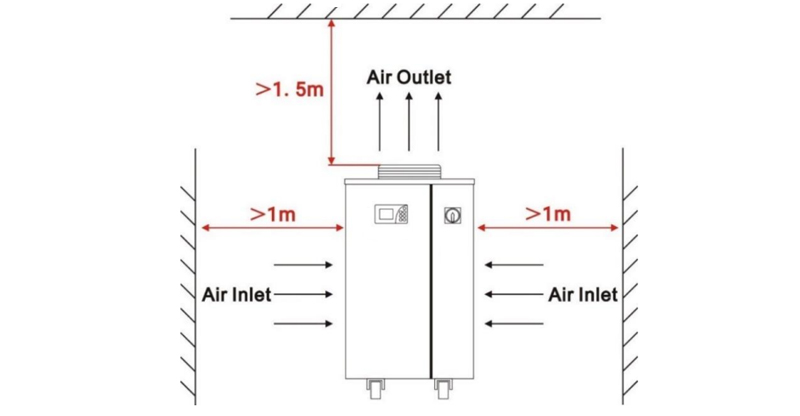

* Compact & Easy to Operate: Space-saving design allows for easy installation, and user-friendly controls ensure simple operation.

* International Certifications: Certified to meet multiple international standards, ensuring quality and safety in diverse markets.

* Durable & Reliable: Built for continuous use, with robust materials and safety protections, including overcurrent and over-temperature alarms.

* 2-Year Warranty: Backed by a comprehensive 2-year warranty, ensuring peace of mind and long-term reliability.

* Wide Compatibility: Suitable for various 3D printers, including SLA, DLP, and UV LED-based printers.

Heater

Water Filter

US standard plug / EN standard plug

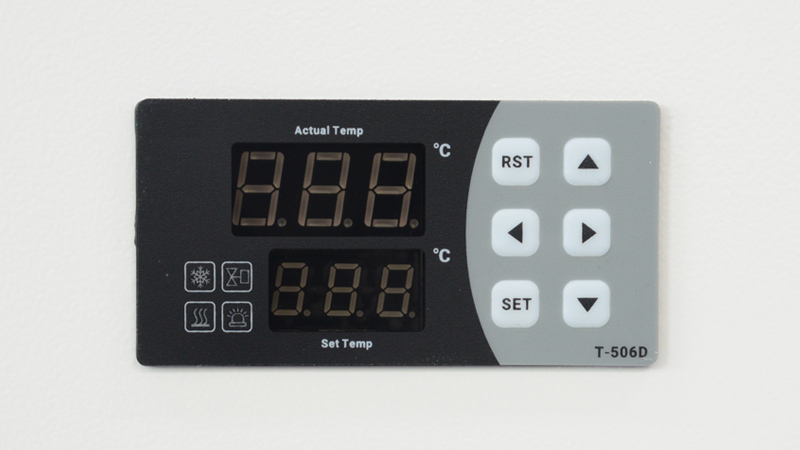

Intelligent temperature controller

The temperature controller offers high precision temperature control of ±0.5°C and two user-adjustable temperature control modes - constant temperature mode and intelligent control mode.

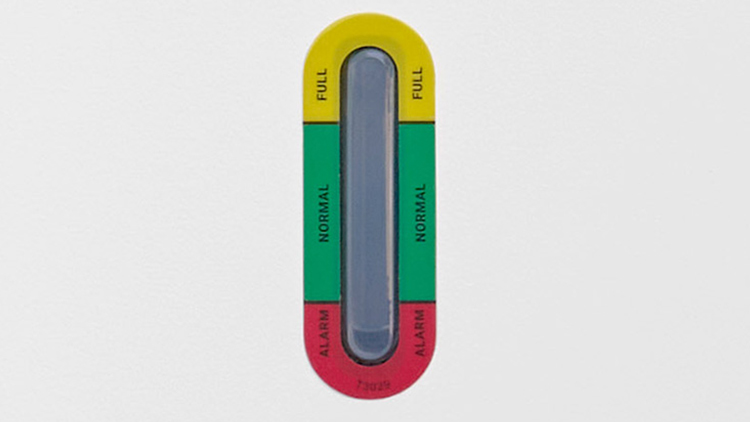

Easy-to-read water level indicator

The water level indicator has 3 color areas - yellow, green and red.

Yellow area - high water level.

Green area - normal water level.

Red area - low water level.

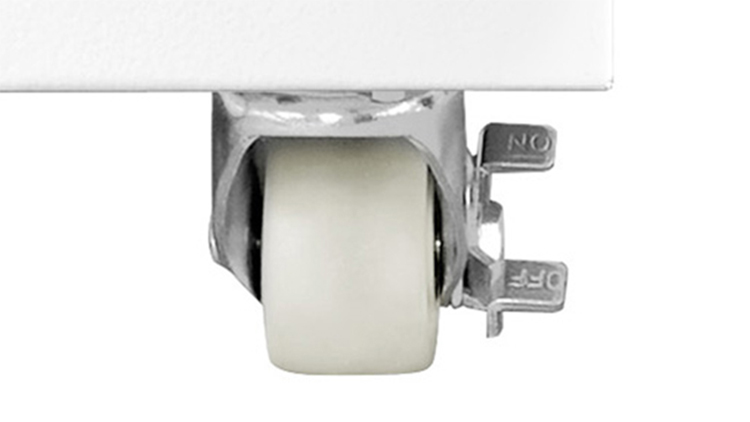

Caster wheels for easy mobility

Four caster wheels offer easy mobility and unmatched flexibility.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Recommended Products

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.