TEYU S&A chillers provide reliable, energy-efficient cooling for CO2 laser equipment, ensuring stable performance and extended lifespan. With advanced temperature control and over 23 years of experience, TEYU offers solutions for various industries, reducing downtime, maintenance costs, and improving production efficiency.

The Critical Role of CO2 Laser Chillers in Modern Applications

CO2 lasers are widely used in industries such as cutting, engraving, medical aesthetics, and more due to their high power and wavelength properties. However, laser tubes generate significant heat during operation, which can lead to temperature fluctuations of ±5°C or more. Without efficient cooling, this can result in:

1. Power Instability: Uncontrolled temperature variations reduce photon emission consistency, degrading cutting/engraving accuracy

2. Accelerated Component Degradation: Optics and laser tubes experience 68% faster aging at uncontrolled temperatures (Optical Engineering Journal, 2022)

3. Unplanned Downtime: Every 1°C overshoot beyond the optimal range increases system failure risk by 15% (Industrial Laser Solutions)

A professional CO2 laser chiller utilizes a closed-loop temperature control system (with precision of ±0.1~1°C) to maintain the laser tube temperature within the optimal operating range (usually 20~25°C), ensuring maximum energy conversion efficiency.

How Does a Chiller Work in CO2 Laser Equipment?

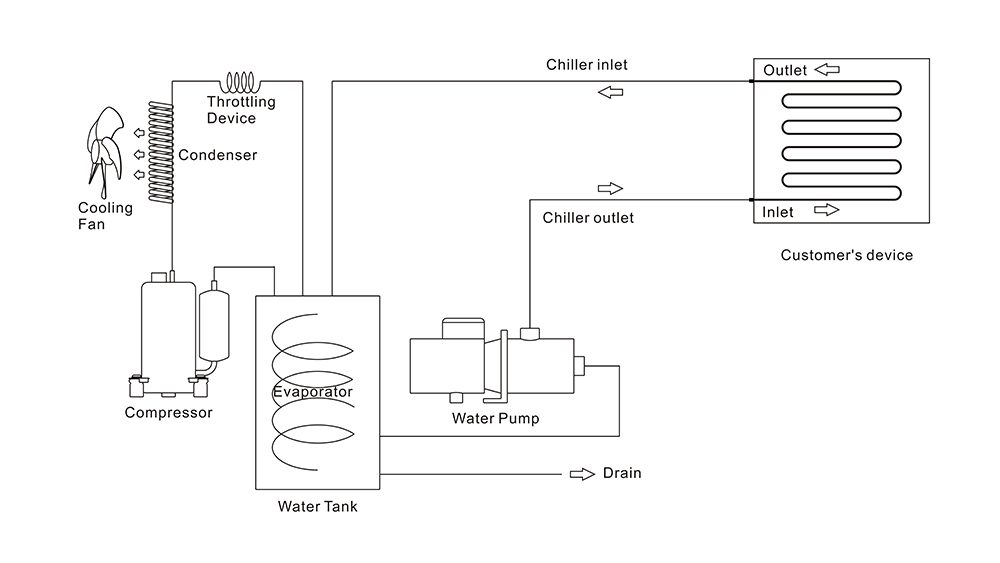

Cooling Principle: The CO2 laser chiller's refrigeration system cools the water, which is then pumped into the CO2 laser equipment. The coolant absorbs heat and warms up before returning to the chiller to be cooled again and recirculated back into the system.

Internal Refrigeration Cycle: The CO2 laser chiller's refrigeration system works by circulating coolant through an evaporator, where it absorbs heat from the returning water, evaporating into steam. The compressor then extracts the steam, compresses it, and sends the high-temperature, high-pressure steam to the condenser. In the condenser, heat is dissipated by a fan, causing the steam to condense into a high-pressure liquid. After passing through an expansion valve, the liquid refrigerant enters the evaporator, where it evaporates again, absorbing more heat. This process repeats, and users can monitor or adjust the water temperature using the temperature controller.

TEYU CO2 Laser Chillers: 3 Competitive Advantages

1. Industry-Leading Expertise

With 23 years of specialization, TEYU S&A is a globally trusted name in CO2 laser cooling. Our dual-brand portfolio (TEYU and S&A) delivers reliable, high-performance chillers, minimizing technical risks for non-specialist users.

2. Dual-Mode Temperature Control

- Smart Mode: Automatically maintains water 2°C below ambient temperature, preventing condensation damage in glass laser tubes.

- Constant Temperature Mode: Manually set precise temperatures (e.g., 20°C) for semiconductor or high-power systems.

Both modes ensure operational flexibility and ease of use, boosting productivity.

3. Compact & Energy-Efficient Design

Optimized component layouts reduce spatial footprint while maximizing cooling efficiency. Premium-grade parts and energy-saving engineering cut long-term operational costs by up to 30%.

Selecting the Right CO2 Laser Chiller: A Practical Guide

| Parameter | Calculation Method | Example Requirement |

| Cooling Capacity | Laser Power (kW) × 1.2 Safety Factor | 1kW × 1.2 = 1.2kW |

| Flow Rate | Laser Spec × 1.5 | 5L/min × 1.5 = 7.5L/min |

| Temp Range | Laser Requirement +2°C Buffer | 15-30°C adjustable |

TEYU Cooling Solution Spotlight:

| Chiller Model | Chiller Features | Chiller Application |

| Chiller CW-3000 | Radiating capacity: 50W/℃ | @<80W CO2 DC Laser |

| Chiller CW-5000 | 0.75kW Cooling Cap., ±0.3℃ Precision | @≤120W CO2 DC Laser |

| Chiller CW-5200 | 1.43kW Cooling Cap., ±0.3℃ Precision | @≤150W CO2 DC Laser |

| Chiller CW-5300 | 2.4kW Cooling Cap., ±0.5℃ Precision | @≤200W DC CO2 Laser |

| Chiller CW-6000 | 3.14kW Cooling Cap., ±0.5℃ Precision | @≤300W CO2 DC Laser |

| Chiller CW-6100 | 4kW Cooling Cap., ±0.5℃ Precision | @≤400W CO2 DC Laser |

| Chiller CW-6200 | 5.1kW Cooling Cap., ±0.5℃ Precision | @≤600W CO2 DC Laser |

| Chiller CW-6260 | 9kW Cooling Cap., ±0.5℃ Precision | @≤400W CO2 RF Laser |

| Chiller CW-6500 | 15kW Cooling Cap., ±1℃ Precision | @≤500W CO2 RF Laser |

Global Success Stories: Proven ROI

Case 1: German Automotive Supplier

Issue: Frequent chiller failures caused 8 hours/month downtime.

Solution: Upgraded to TEYU CW-7500 industrial chiller.

Result: 19% OEE improvement, ROI in 8 months.

Case 2: Brazilian Laser Equipment Distributor

Issue: High failure rates with the previous chiller brand.

Solution: Switched to TEYU as OEM partner.

Result: 92% fewer complaints, 20% sales growth.

Optimize Your CO2 Laser Performance Today

TEYU CO2 laser chillers combine precision engineering, operational flexibility, and energy efficiency to protect critical laser systems across industries. Backed by decades of R&D and global client validation, our solutions deliver unmatched reliability and rapid ROI.

Optimize your laser performance – Partner with TEYU for tailored cooling solutions.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.