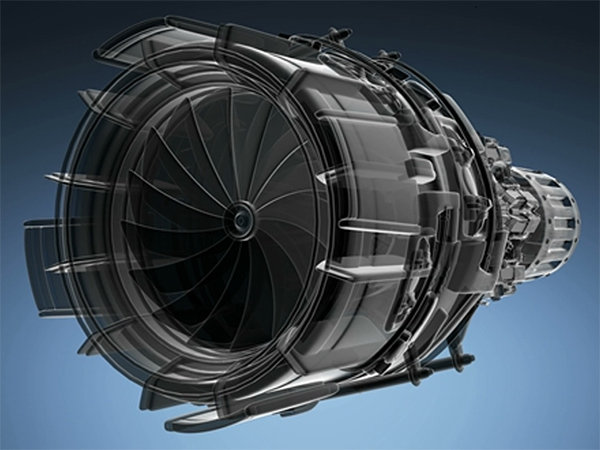

Ultrafast laser technology, enabled by advanced cooling systems, is rapidly gaining prominence in aircraft engine manufacturing. Its precision and cold processing capabilities offer significant potential to enhance aircraft performance and safety, driving innovation within the aerospace industry.

In the aerospace industry, technological innovations continually drive improvements in aircraft performance and safety. Today, we explore an advanced technology leading a new wave in aerospace engine manufacturing — ultrafast laser technology — and how the TEYU ultrafast laser chiller provides stable support for this technology.

Unique Advantages of Ultrafast Laser Technology

Ultrafast lasers, with their ability to generate high-intensity light pulses in extremely short durations, exhibit unique charm in the aerospace sector. Compared to traditional laser processing methods, ultrafast laser technology revolutionizes aerospace engine manufacturing with its high precision and cold processing capabilities. Its processing mechanism directly affects the electronic state, rapidly transferring energy to the material lattice, breaking bonds, and expelling material in the form of plasma, achieving efficient material removal with no thermal impact.

Applications of Ultrafast Laser Technology in Aerospace Engine Manufacturing

Processing Cooling Holes in Turbine Blades: One of the key components of aircraft engines is turbine blades, whose cooling hole structure on the surface is crucial to engine performance. Ultrafast laser technology, especially femtosecond lasers, has successfully solved the problems of coating delamination and cracking in traditional processing methods, providing a new solution for the production of cooling holes in aircraft engines.

Processing Cooling Holes in Combustor Liner: Combustor liners, essential components of combustion chambers, require effective cooling. Ultrafast laser technology, such as picosecond laser applications, can produce cooling holes on surfaces without extensive peeling, layering, or dimensional discrepancies, significantly enhancing the lifespan of combustor liners.

Processing Irregular Grooves: Ultrafast laser technology, with its high energy density and short processing times, provides a new means for the processing of irregular grooves in high-precision aircraft engine components, ensuring efficient and accurate processing.

Stable Cooling of TEYU Ultrafast Laser Chillers

In the application of ultrafast laser technology, ultrafast laser chillers play an indispensable role. The highly efficient cooling function of the chiller provides a stable operating environment for the ultrafast laser, ensuring its continuous and stable operation. TEYU ultrafast laser chillers boast temperature stability of ±0.08℃, and by precisely controlling the temperature of the laser, they further improve the precision of ultrafast laser processing, providing strong technical support for aircraft engine manufacturing.

Ultrafast laser technology, with its high precision and cold processing characteristics, is becoming a new favorite in the field of aircraft engine manufacturing. In the future, ultrafast laser technology will inject new vitality into the development of the aviation industry and contribute to the continuous improvement of aircraft performance and safety.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.