In the manufacturing industry, laser welding has become an important processing method, with handheld laser welding being particularly favored by welders due to its flexibility and portability. Various types of TEYU welding chillers are available for widespread use in metallurgy and industrial welding, including for laser welding, traditional resistance welding, MIG welding and TIG welding, improving welding quality and welding efficiency, and extending the lifespan of welding machines.

With the rapid advancement of technology, laser technology has gradually infiltrated various aspects of our daily lives. Especially in the manufacturing industry, laser welding has become an important processing method, with handheld laser welding being particularly favored by welders due to its flexibility and portability.

1. Principles and Features of Handheld Laser Welding

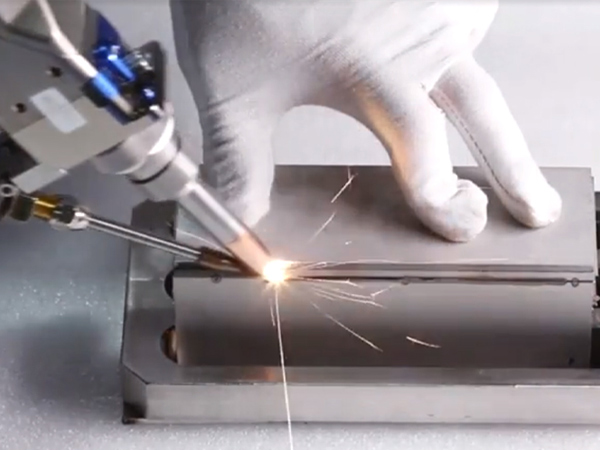

Handheld laser welding is a flexible and efficient laser welding technology. It utilizes a high-energy laser beam as a heat source, focusing it on the metal surface through an optical system to melt the metal via thermal conduction, achieving welding. Handheld laser welding equipment typically consists of a laser, optical system, power supply, and control system. It is characterized by its small size, lightweight, and ease of operation, making it adaptable to various working environments.

2. Differences Between Handheld Laser Welding and Traditional Welding

Energy Source and Transmission Method

Traditional welding mainly relies on the high-temperature melting of metals generated by an electric arc to accomplish the welding process. Handheld laser welding, on the other hand, uses a high-energy laser beam to irradiate the metal surface, melting the metal via thermal conduction to achieve welding. Consequently, handheld laser welding exhibits characteristics such as high energy density, concentrated heating, and fast welding speed.

Welding Speed

Handheld laser welding boasts significantly higher welding speed and efficiency compared to traditional methods. Thanks to the high energy density of the laser beam, metals can be rapidly melted, achieving deep fusion welding effects, while minimizing the heat-affected zone and reducing workpiece deformation. These qualities grant handheld laser welding a notable advantage in mass production.

Welding Results

Handheld laser welding excels in welding dissimilar steels and metals. It offers high speed, minimal distortion, and a small heat-affected zone. Weld seams appear beautiful, smooth, with few to no pores and no pollution. Handheld laser welding machines can handle tiny part openings and precise welding. In contrast, traditional welding seams are susceptible to defects like pores and slag inclusion due to factors such as operator skill and environmental conditions.

Operational Difficulty

Handheld laser welding equipment requires less reliance on the welder's skill, making it quick to adapt to and cost-effective in terms of labor. Conversely, traditional welding demands higher skill levels and experience, posing greater operational challenges. Therefore, handheld laser welding presents a lower barrier to entry in terms of operation and is suitable for widespread applications.

3. Advantages of TEYU Welding Chillers

Various types of TEYU welding chillers are available for widespread use in metallurgy and industrial welding, including for laser welding, traditional resistance welding, MIG welding and TIG welding, improving welding quality and welding efficiency, and extending the lifespan of welding machines.

TEYU CW-Series welding chillers are ideal temperature control solutions for cooling traditional resistance welding, MIG welding and TIG welding, which offers cooling precision from ±1℃ to ±0.3℃ and refrigeration capacity from 700W to 42000W. With a precise water-cooling temperature control system, it can maintain stable laser output over extended periods, effortlessly handling various demanding work conditions.

As for laser welding, TEYU CWFL-Series welding chillers are designed with dual temperature control functions and are applicable to cool 1000W to 60000W fiber lasers. Fully considering usage habits, the RMFL-Series welding chillers are rack-mounted design and the CWFL-ANW-Series welding chillers are all-in-one design. With dual temperature control to cool the laser and optics/welding gun at the same time, intelligent temperature control, portable and environmentally friendly, providing efficient and stable cooling for 1000W-3000W handheld laser welding machines.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.