Cooling capacity and cooling power are closely related yet distinct factors in industrial chillers. Understanding their differences is key to choosing the right industrial chiller for your needs. With 22 years of expertise, TEYU leads in providing reliable, energy-efficient cooling solutions for industrial and laser applications globally.

In the realm of industrial chillers, cooling capacity and cooling power are two closely related but distinct parameters. Understanding their differences and interrelation is essential for selecting the most suitable industrial chiller for your application.

Cooling Capacity: The Measure of Cooling Performance

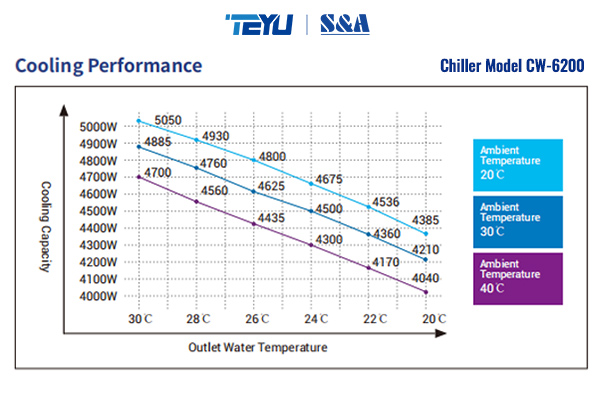

Cooling capacity refers to the amount of heat an industrial chiller can absorb and remove from the cooled object within a unit of time. It directly determines the industrial chiller’s cooling performance and application scope—essentially, how much cooling the machine can provide.

Typically measured in watts (W) or kilowatts (kW), cooling capacity can also be expressed in other units such as kilocalories per hour (Kcal/h) or refrigeration tons (RT). This parameter is crucial in evaluating whether an industrial chiller can handle the thermal load of a specific application.

Cooling Power: The Measure of Energy Consumption

Cooling power, on the other hand, represents the amount of electrical energy consumed by the industrial chiller during operation. It reflects the energy cost of running the system and indicates how much power the industrial chiller needs to deliver the desired cooling effect.

Cooling power is also measured in watts (W) or kilowatts (kW) and serves as a key factor in assessing the industrial chiller's operational efficiency and cost-effectiveness.

The Relationship Between Cooling Capacity and Cooling Power

In general, industrial chillers with higher cooling capacity often consume more electricity, resulting in higher cooling power. However, this relationship is not strictly proportional, as it is influenced by the chiller’s energy efficiency ratio (EER) or coefficient of performance (COP).

The energy efficiency ratio is the ratio of cooling capacity to cooling power. A higher EER indicates that the chiller can generate more cooling with the same amount of electrical energy, making it more energy-efficient and cost-effective.

For example: An industrial chiller with a cooling capacity of 10 kW and a cooling power of 5 kW has an EER of 2. This means the machine delivers two times the cooling effect compared to the energy it consumes.

Choosing the Right Industrial Chiller

When selecting an industrial chiller, it is essential to evaluate cooling capacity and cooling power alongside efficiency metrics such as EER or COP. This ensures that the chosen chiller not only meets cooling requirements but also operates efficiently and cost-effectively.

At TEYU, we have been at the forefront of industrial chiller innovation for 22 years, offering reliable and energy-efficient cooling solutions to industries worldwide. Our chiller product range includes models tailored for a variety of applications, from laser systems to precision machinery. With a reputation for exceptional performance, durability, and energy savings, TEYU chillers are trusted by leading manufacturers and integrators.

Whether you need a compact chiller for space-limited applications or a high-capacity system for demanding laser processes, TEYU provides expert consultation and customized solutions. Contact us today via [email protected] to discover how our industrial chillers can enhance your operations and reduce energy costs.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.