What is laser cleaning? Laser cleaning is the process of removing materials from solid (or sometimes liquid) surfaces through the irradiation of laser beams. Currently, laser cleaning technology has matured and found applications in several areas. Laser cleaning requires a suitable laser chiller. With 21 years of expertise in laser processing cooling, two cooling circuits to simultaneously cool the laser and optical components/cleaning heads, Modbus-485 intelligent communication, professional consulting and after-sales service, TEYU Chiller is your trustworthy choice!

One class of essential materials used in industries such as aviation, aerospace, automotive, mechanical manufacturing, shipbuilding, and chemical engineering is non-ferrous metal structural materials. However, prolonged usage of these materials leads to the formation of oxide layers, affecting both their appearance and practical use.

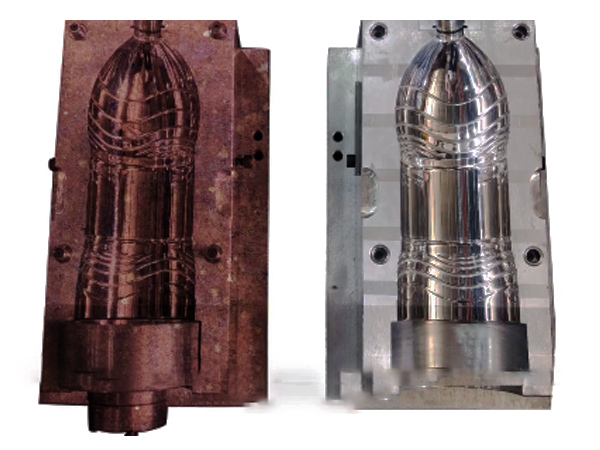

In the past, acid cleaning was primarily employed to remove oxide layers. However, acid cleaning not only damages the materials but also causes environmental pollution. Laser cleaning, on the other hand, offers a perfect solution to these challenges.

But What Exactly Is Laser Cleaning?

Laser cleaning is the process of removing materials from solid (or sometimes liquid) surfaces through the irradiation of laser beams.

Contaminants on the surface of metal materials mainly include oxide layers (rust layers), paint coatings, and other adherents. These contaminants can be categorized into organic pollutants (such as paint coatings) and inorganic pollutants (such as rust layers).

Oxide layers have excellent absorbability for P-LASER lasers, enabling their vaporization and effective removal. The oxides quickly vaporize under the tiny plasma burst generated by the pulsed laser beam, detach from the target surface, and ultimately result in a clean surface with no oxide residue.

Laser cleaning technology is an advanced technique with broad prospects for research and application in high-precision fields such as aerospace, military equipment, electronics, and electrical engineering. Currently, laser cleaning technology has matured and found applications in several areas. Thanks to its efficiency, environmental friendliness, and excellent cleaning performance, the scope of its applications is gradually expanding.

Laser Cleaning Requires a Suitable Laser Chiller

Laser cleaning is achieved through the use of lasers, and to ensure stable beam output for effective cleaning, the temperature is often a crucial factor. With 21 years of expertise in laser processing cooling, Guangzhou Teyu specializes in providing the CWFL series laser chillers, which are suitable for laser cleaning. TEYU water chillers are equipped with two modes: constant temperature and intelligent temperature control. The two cooling circuits can simultaneously cool the laser and optical components/cleaning heads. With Modbus-485 intelligent communication, monitoring and management become convenient. Guangzhou Teyu also provides professional consulting and after-sales service, with an annual sales volume exceeding 120,000 units. TEYU Chiller is the trustworthy choice!

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.