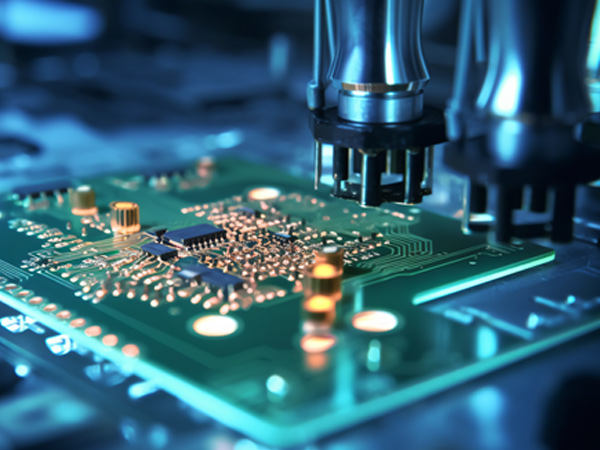

PCB laser depaneling machine is a device that uses laser technology to accurately cut printed circuit boards (PCBs) and is widely used in the electronics manufacturing industry. A laser chiller is needed to cool the laser depaneling machine, which can effectively control the temperature of the laser, ensure optimal performance, extend the service life, and improve the stability and reliability of the PCB laser depaneling machine.

The PCB laser depaneling machine is a device that uses laser technology to precisely cut printed circuit boards (PCBs). By controlling the movement trajectory of a high-energy laser beam on the surface of the material, it achieves precise cutting of PCB boards. This equipment is widely used in the electronics manufacturing industry, especially for depaneling operations that require high precision and efficiency.

Advantages of PCB Laser Depaneling Machines

High Efficiency: The laser depaneling machine uses a high-energy laser beam for cutting, allowing it to complete large-scale depaneling tasks in a short time. Compared to traditional mechanical cutting methods, the laser depaneling machine increases depaneling speed by more than 20%, significantly boosting production efficiency.

High Precision: The laser depaneling machine can achieve sub-millimeter precision, meeting the production needs of fine electronic products. The high energy density and strong controllability of laser technology ensure smooth cutting edges and consistent dimensions.

Strong Adaptability: The laser depaneling machine is suitable for various types of circuit boards, including rigid, flexible, and composite boards. Whether it's single-layer or multi-layer boards, the laser depaneling machine can adapt to and meet the depaneling requirements.

Automation Features: The laser depaneling machine is equipped with automatic positioning, automatic correction, and automatic scaling functions, enabling unattended production processing. This reduces human error, increases work efficiency, and enhances safety.

Non-Contact Processing: The laser depaneling machine uses non-contact processing, avoiding the damage and burrs that can occur with mechanical cutting, ensuring the flatness and quality of the PCB surface.

Multi-Material Compatibility: The laser depaneling machine is compatible with various materials, such as FPC (flexible circuit boards), PCB, RFPC (radio frequency circuit boards), IC substrate ceramics, and more, offering strong versatility and applicability.

The Necessity of Laser Chiller

During operation, the stability and precision of the laser source in a PCB laser depaneler are critical to the quality of the cutting. To maintain the laser's operating temperature within an appropriate range and prevent performance degradation or damage due to excessive heat, some high-performance laser depaneling machines may require a laser chiller for cooling. A laser chiller effectively controls the laser's temperature, ensuring optimal performance even during continuous operation or in high-temperature environments. Additionally, using a laser chiller can extend the laser's lifespan and improve the equipment's stability and reliability.

TEYU S&A Chiller Manufacturer, with 22 years of experience in the refrigeration industry, has developed over 120 laser chiller models to meet the cooling needs of various laser equipment. With a 2-year warranty, an annual shipment volume of 160,000 chiller units, and sales in over 100 countries and regions, TEYU S&A Chiller Manufacturer is your trusted partner. Quato us to get your tailored cooling solution. Please write to us for your customized cooling solution.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.