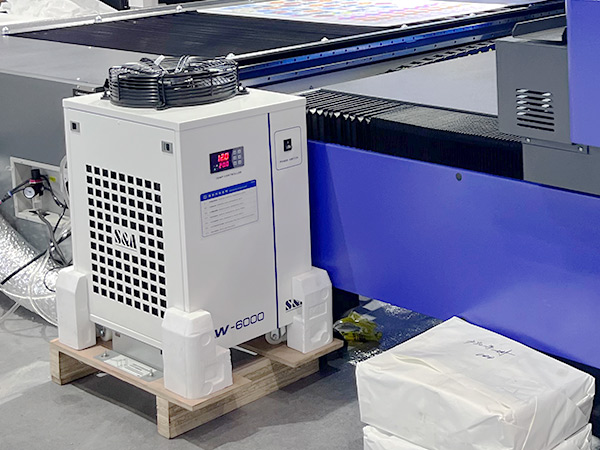

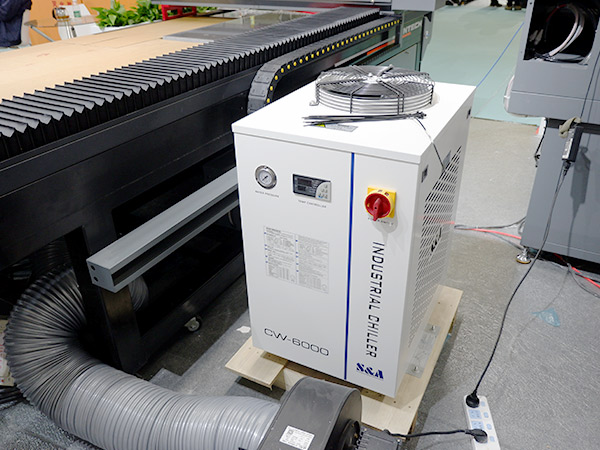

CO2 laser processing machines are suitable for processing a wide range of materials, including plastic, acrylic, wood, plastic, glass, fabric, paper, etc. A 3000W cooling capacity chiller, with its robust cooling capacity and versatility, is an ideal choice for a wide array of CO2 laser cutting, engraving, and marking machines. Its ability to handle the heat generated by these machines ensures optimal performance and extends the lifespan of the equipment, making it a valuable addition to any precision manufacturing operation.

In precision manufacturing, the demand for high-performance cutting equipment is ever-growing. Among the various cutting technologies available, CO2 laser cutting stands out for its precision, speed, and versatility, which has a wide range of materials, including plastics, acrylic, wood, plastics, glass, fabrics, paper, and more. To ensure the optimal performance of such CO2 laser cutting machines, a reliable and efficient cooling system(CO2 laser chiller) is crucial.

A 3000W water chiller, with its substantial cooling capacity, can ensure consistent and reliable cooling, which is crucial for maintaining the optimal operating temperature of the CO2 laser. This not only prolongs the lifespan of the laser tube but also enhances the precision and accuracy of the cuts, resulting in smoother, cleaner edges.

A 3000W cooling capacity water chiller is well-suited for a wide range of CO2 laser cutting and engraving machines. Whether it's a small, desktop-sized laser cutter or a large, industrial-grade machine, a 3000W water chiller can provide the necessary cooling to ensure stable and efficient operation.

For instance, in high-power CO2 laser cutting machines used for heavy-duty applications like cutting through thick metal sheets or plastics, the 3000W cooling capacity chiller can effectively dissipate the heat generated by the laser beam, preventing overheating and ensuring continuous, uninterrupted cutting.

Moreover, a 3000W water chiller is also compatible with CO2 laser engraving machines, which require precise temperature control for intricate designs and fine details. The consistent cooling provided by the water chiller ensures that the laser beam remains stable, resulting in crisp and accurate engravings.

Additionally, the 3000W water chiller's compatibility extends to CO2 laser marking systems as well. These systems are often used for marking and branding purposes on various materials. The 3000W chilling capacity chiller ensures that the laser marking process is not interrupted by overheating, thus maintaining the quality and consistency of the marks.

What's more, the 3000W water chiller's design often takes into account the specific requirements of different CO2 laser equipment. For example, it may have multiple output ports to accommodate multiple laser heads or feature adjustable cooling parameters to cater to varying cutting speeds and depths.

In summary, a 3000W cooling capacity chiller, with its robust cooling capacity and versatility, is an ideal choice for a wide array of CO2 laser cutting, engraving, and marking machines. Its ability to handle the heat generated by these machines ensures optimal performance and extends the lifespan of the equipment, making it a valuable addition to any precision manufacturing operation.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.