How to Choose a Suitable Laser Chiller for Your 6000W Fiber Laser Cleaning Machine? It involves considering a few factors, such as chiller cooling capacity, temperature stability, cooling method, chiller brand, etc.

When choosing a laser chiller for your 6000W fiber laser cleaning machine, you need to consider some factors, such as the cooling capacity of the laser chiller, the temperature stability, the cooling method, the chiller brand, etc. Here are some tips for you:

First, you need to determine the cooling capacity required for your laser. This is typically measured in kilowatts (kW) and should match or exceed the power output of your laser. TEYU CWFL-6000 laser chiller is specially designed by TEYU S&A chiller manufacturer for 6000 fiber laser, perfect for cooling 6000W laser cleaning machines, 6000W laser welding machines, 6000W laser cutting machines, 6000W laser engraving machines, etc.

Next, you should consider the temperature stability required for your laser system. Some lasers are more sensitive to temperature fluctuations than others, so it's important to choose a chiller that can maintain a stable temperature within the desired range. TEYU CWFL-6000 laser chiller has a water temperature control range of 5°C ~35°C and a precision of ±1℃, perfectly meeting the temperature control range and precision requirements of 6000W fiber lasers on the market.

You may also want to consider the cooling method used by the laser chiller, which depends on your specific needs and available resources.

Refrigeration Principle Of TEYU Chiller For Supporting Equipment: The laser chiller's refrigeration system cools the water, and the water pump delivers the low-temperature cooling water to the laser equipment that needs to be cooled. As the cooling water takes away the heat, it heats up and returns to the chiller, where it is cooled again and transported back to the fiber laser equipment.

Refrigeration Principle Of The TEYU Laser Chiller Itself: In the refrigeration system of a chiller, the refrigerant in the evaporator coil absorbs the heat of the return water and vaporizes into steam. The compressor continuously extracts the generated steam from the evaporator and compresses it. The compressed high-temperature, high-pressure steam is sent to the condenser and later releases heat (heat extracted by the fan) and condenses into a high-pressure liquid. After being reduced by the throttling device, it enters the evaporator to be vaporized, absorbs the heat of the water, and the whole process circulates constantly. You can set or observe the working status of the water temperature through the temperature controller.

Additionally, it's important to consider the size and weight of the chiller, as well as any space limitations you may have in your facility. You'll want to ensure that the chiller can be easily installed and integrated into your laser system. All of TEYU's chillers are specially designed by TEYU's R&D team, combining the smallest volume and maximum cooling capacity to produce the best cost-effective products.

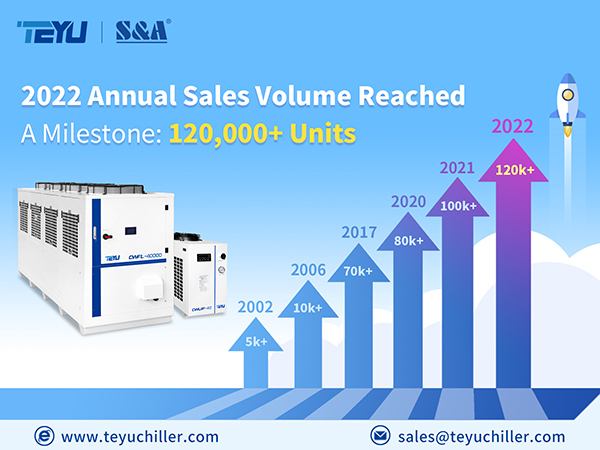

Lastly, it's always a good idea to consult with the chiller manufacturer or an expert in laser cooling systems to ensure you choose the most suitable chiller for your specific application. They can provide you with more specific recommendations based on the details of your laser cleaning machine. TEYU S&A Chiller has 21 years of experience in laser cooling. In 2022, the sales volume of chiller products has exceeded 120,000 units, selling well in more than 100 countries and regions around the world. Welcome to consult TEYU S&A professional team at [email protected] for your optimal laser cooling solution.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.