As the cool and cold weather sets in, TEYU S&A has received inquiries from our customers regarding the maintenance of their industrial water chillers. In this guide, we will walk you through essential points to consider for winter chiller maintenance.

As the cool and cold weather sets in, TEYU S&A has received inquiries from our customers regarding the maintenance of their industrial water chillers. In this guide, we will walk you through essential points to consider for winter chiller maintenance.

1. Optimal Chiller Placement and Dust Removal

(1)Chiller Placement

Ensure the air outlet (cooling fan) is positioned at least 1.5m away from obstacles.

Keep the air inlet (filter gauze) at least 1m away from obstacles for efficient heat dissipation.

(2)Cleaning & Dust Removal

Regularly use a compressed air gun to clean the dust on the filter gauze and the surface of the condenser to prevent inadequate heat dissipation.

*Note: Maintain a safe distance (approximately 15cm) between the air gun outlet and the condenser fins during cleaning. Direct the air gun outlet vertically toward the condenser.

2. Schedule Replacement of Circulating Water

Over time, the circulating water can develop mineral deposits or scale buildup, which may interfere with the normal operation of the system.

To minimize issues and ensure a smooth water flow, it is recommended to replace the circulating water every 3 months using purified or distilled water.

3. Regular Inspections

Periodically check the chiller's cooling system, including cooling water pipes and valves, for any leaks or blockages. Address issues promptly to ensure normal operation.

4. For Areas Below 0℃, Antifreeze Is Essential for Chiller Operation.

(1)The importance of Antifreeze

In chilly winter conditions, adding antifreeze is crucial to shield the cooling liquid, preventing freezing that could lead to pipe cracking in laser and chiller systems, which could threaten their leak-proof integrity.

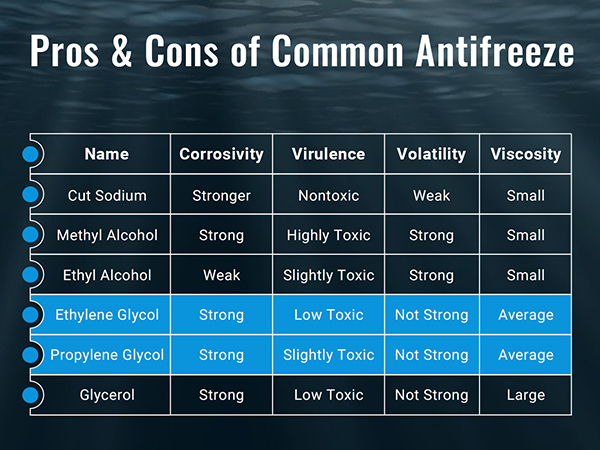

(2)Careful Selection of the Right Antifreeze Is Crucial. Consider the 5 Key Factors:

* Effective anti-freeze performance

* Anticorrosive and rust-resistant properties

* No swelling and erosion for rubber sealing conduit

* Moderate low-temperature viscosity

* Stable chemical property

(3)Three Important Principles of Antifreeze Usage

* Lower concentration is preferable. Most antifreeze solutions tend to be corrosive, so, within the limits of maintaining effective freeze performance, a lower concentration is better.

* Shorter usage duration is preferred. When temperatures consistently exceed 5℃, it is recommended to completely drain the antifreeze and thoroughly flush the chiller with purified water or distilled water. Subsequently, replace it with the usual purified water or distilled water.

* Different antifreeze should not be mixed. Despite having similar ingredients, various brands may differ in their additive formulas. It is advisable to consistently use the same brand of antifreeze to prevent potential chemical reactions, precipitation, or the formation of bubbles.

(4)Antifreeze Types

The prevalent antifreeze options for industrial chillers are water-based, employing ethylene glycol and propylene glycol.

(5)Proper Mixing Ratio Preparation

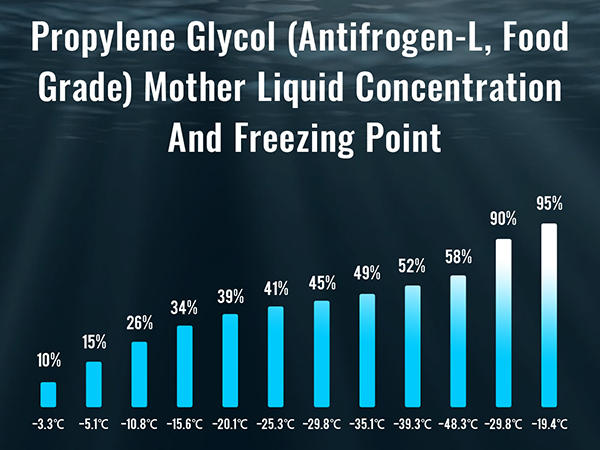

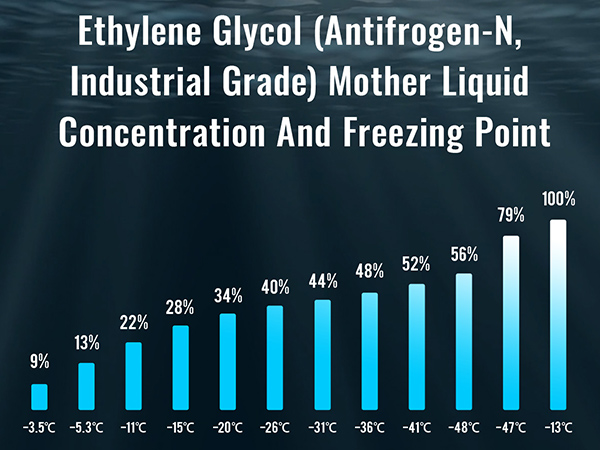

Users should calculate and prepare a suitable antifreeze ratio based on the winter temperature in their region. Following the ratio determination, the prepared antifreeze mixture can then be added to the industrial chiller, ensuring optimal performance and longevity.

*Note: (1)To ensure the safety of the chiller and laser equipment, please adhere strictly to the antifreeze-to-water ratio, preferably not exceeding 3:7. It is recommended to keep the antifreeze concentration below 30%. High-concentration antifreeze may cause potential blockages in the pipes and corrosion of equipment components. (2)Some types of lasers may have specific antifreeze requirements. Before adding the antifreeze, it's recommended to consult the laser manufacturer for guidance.

(6)Example Illustration

As an illustration, we use the water chiller CW-5200, which has a 6-liter water tank. If the lowest winter temperature in the region is around -3.5°C, we can use a 9% volume concentration of ethylene glycol antifreeze mother solution. This means a ratio of approximately 1:9 [ethylene glycol: distilled water]. For water chiller CW-5200, this translates to approximately 0.6L of ethylene glycol and 5.4L of distilled water to create a mixed solution of around 6L.

(7)Steps for Adding Antifreeze to TEYU S&A Chillers

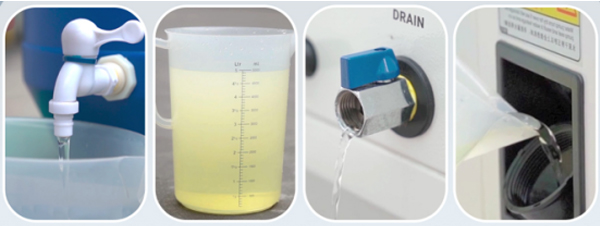

a. Prepare a container with measurements, antifreeze (mother solution), and the distilled or purified water needed for the chiller.

b. Dilute the antifreeze with purified water or distilled water according to the specified ratio.

c. Turn off the water chiller's power, then unscrew the water-filling port.

d. Turn on the drain valve, empty the circulating water from the tank, and then tighten the valve.

e. Add the diluted mixed solution into the chiller through the water-filling port while monitoring the water level.

f. Tighten the cap of the water-filling port, and start the industrial chiller.

(8)Maintain 24/7 Chiller Operation

For temperatures below 0℃, it is recommended to operate the chiller continuously, 24 hours a day, if conditions permit. This guarantees a steady flow of cooling water, preventing the possibility of freezing.

5. If the Chiller Is Inactive During Winter, the Following Steps Should Be Taken:

(1)Drainage: Before long-term shutdown, drain the chiller to prevent freezing. Open the drain valve at the bottom of the equipment to let out all the cooling water. Disconnect the water inlet and outlet pipes, and open the water filling port and drain valve for internal drainage.

Following the drainage process, use a compressed air gun to thoroughly dry the interior pipelines.

*Note: Avoid blowing air at the joints where yellow tags are pasted near the water inlet and outlet, as it may cause damage.

(2)Storage: After completing the drainage and drying procedures, securely reseal the chiller. It is recommended to temporarily store the equipment in a location that does not disrupt production. For water chillers exposed to outdoor conditions, consider implementing insulation measures, such as wrapping the equipment with insulating materials, to minimize temperature fluctuations and prevent the ingress of dust and airborne moisture.

During winter chiller maintenance, prioritize tasks such as monitoring antifreeze fluid, conducting regular inspections, and ensuring proper storage procedures. For any further assistance or inquiries, please feel free to reach out to our dedicated customer service team at [email protected]. Additional details regarding the maintenance of TEYU S&A industrial water chillers can be found by visiting https://www.teyuchiller.com/installation-troubleshooting_nc7.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.