Semiconductor manufacturing processes require high efficiency, high speed and more refined operating procedures. The high efficiency and stability of laser processing technology make it widely used in the semiconductor industry. TEYU laser chiller is equipped with advanced laser cooling technology to keep the laser system running at low temperatures and prolong the lifespan of laser system components.

The semiconductor industry includes the design, development, manufacture and sale of small electronic components and chips. With continuous innovation and breakthroughs in science and technology, the semiconductor industry has developed rapidly. As semiconductor production increases, manufacturers want to produce more semiconductor products in less time. Additionally, as modern electronic devices become smaller, semiconductors must become smaller as well. Therefore, the semiconductor manufacturing process requires high efficiency, high speed and more refined operating procedures. The high efficiency and stability of laser processing technology make it widely used in the semiconductor industry.

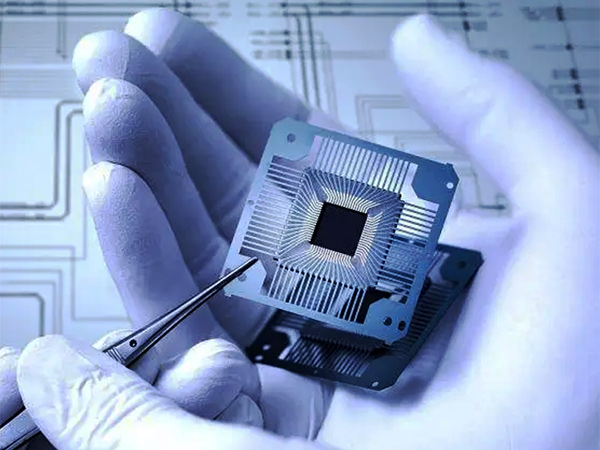

Application of Laser Technology in Chip Manufacturing

Laser technology has become a critical technique in the semiconductor industry. It offers significant advantages such as high precision, efficiency, and stability, enabling precise processing and etching at the microscale, and providing strong support for chip manufacturing. Particularly in the production of high-density integrated circuits and microelectronic devices, laser technology has become an indispensable tool and technique.

Applications of Laser Technology in the Semiconductor Industry

Laser technology is primarily applied in the semiconductor industry in 4 areas: 1) the use of lasers for LED wafer dicing, 2) laser marking techniques, 3) laser pulse annealing, and 4) the application of laser technology in the LED industry.

These applications have greatly facilitated the transformation and advancement of the semiconductor industry, accelerating its development pace.

Laser Chiller Ensures Performance and Precision of Laser Systems

Excessive temperatures can cause wavelength increases, thereby affecting the performance of laser systems. Additionally, many laser applications require strong beam focusing, making the operating temperature crucial for beam quality. Low-temperature operation can also prolong the lifespan of laser system components. Therefore, we recommend using TEYU chiller with its advanced temperature control technology. TEYU laser chillers are suitable for fiber lasers, CO2 lasers, semiconductor lasers, ion lasers, solid-state lasers, and more. They provide a cooling capacity of up to 42,000W and precise temperature control within ±0.1℃. These water chillers are highly efficient, energy-saving, environmentally friendly, and come with reliable after-sales support. Each TEYU chiller undergoes standardized testing, with an annual shipment volume of 120,000 units, making TEYU your dependable partner.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.