Ultrasonic welding is the go-to method for various plastic components in electronics, automotive, toys, and consumer goods. Meanwhile, laser welding is gaining attention, offering unique benefits. As laser plastic welding continues to grow in market applications and demand for higher power rises, industrial chillers will become an essential investment for many users.

Plastic, one of humanity's most transformative inventions, is now integral across thousands of sectors, from packaging to electronics, automotive, healthcare, and beyond. With its versatility, plastic can be classified as either rigid or flexible and is molded through processes like extrusion, blow molding, and injection molding. Some components are ready-made in a single step, while others require further refinement to meet end-product requirements.

Meeting the Growing Demand for Plastic Processing: The Role of Laser Welding

Many plastic parts can be directly assembled after molding. However, complex products often require plastic components to be modified or joined with other materials. Due to the diverse types of plastics, choosing the right processing method and equipment—tailored to each plastic's properties—is crucial.

Currently, most plastic processing relies on mechanical techniques, including sawing, shearing, drilling, grinding, polishing, and threading. Common industrial plastics, such as PP, ABS, PET, PVC, and acrylic, are typically cut with mechanical saw blades, which are highly dependent on manual operation. This often leads to issues with precision, high defect rates, and the need for secondary finishing to remove burrs.

For drilling, mechanical drills are the most widely used for plastic components. Due to the tendency of plastic polymers to be damaged by metal drill bits, mechanical drilling is relatively fast but often produces plastic debris and burrs along the edges. Despite these drawbacks, mechanical drilling remains the most mature and popular method for plastic components.

Let’s take a closer look at plastic welding technologies. Plastic is heat-sensitive, so welding it typically involves melting or softening to join parts. Techniques like hot plate welding suit large plastic pieces with broad contact areas.

(Ultrasonic Welding)

Ultrasonic welding is the go-to method for various plastic components in industries like electronics, automotive, toys, cosmetics, and consumer goods. This method uses high-frequency mechanical energy to generate instant heat and bond plastic surfaces.

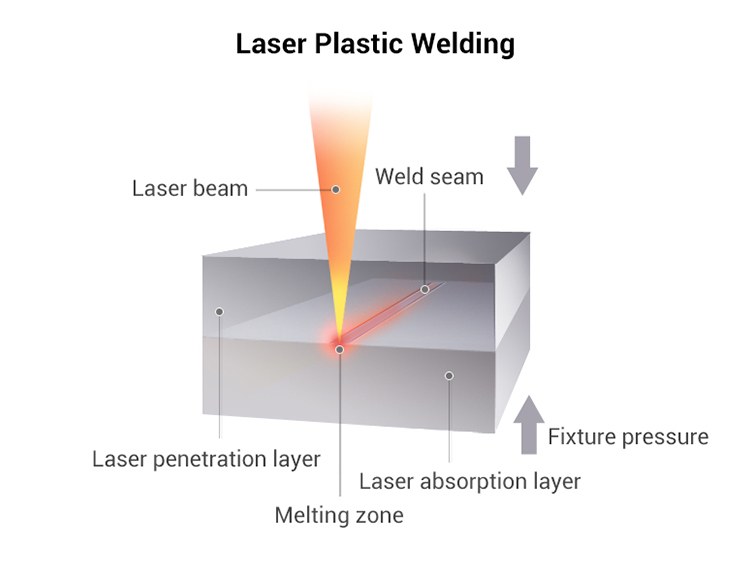

Meanwhile, laser welding—a newer method—is gaining attention. By applying laser-generated heat precisely at the joint, laser welding offers unique benefits. What potential breakthroughs could laser bring to plastic processing?

Exploring Laser Processing Potential in Plastic Manufacturing: Lower Equipment Costs May Be an Advantage

Laser marking is already widely used in plastic processing, especially for labeling items like cables, chargers, and appliance casings. UV laser marking technology is mature and well-suited for adding brand logos or product details on plastic surfaces.

For cutting and drilling, however, laser processing faces challenges. The heat sensitivity of plastic can lead to melting or burning, making it difficult to achieve clean cuts without dark or scorched edges. While transparent plastic cannot yet be cut with lasers, darker plastics have potential with high-frequency, high-power pulsed lasers. As laser technology advances—especially in ultrashort pulse lasers—plastic cutting may become increasingly viable.

As mentioned, laser welding of plastics is a new technology offering advantages like fast speed, high precision, strong seals, a pollution-free process, and solid joints, suitable for applications in automotive, medical devices, and consumer electronics. However, despite being in the market for several years, laser plastic welding remains a niche, mainly challenged by ultrasonic equipment. Cost is one issue, with laser plastic welding machines costing tens of thousands of yuan, while ultrasonic machines cost only a few thousand. Additionally, laser processes still require further exploration for different types of plastics. Ultrasonic welding is also suitable for automated processing with high speed and efficiency, though it has noise pollution issues and lower precision and sealing than laser welding.

With ongoing reductions in laser and related equipment prices, the cost of laser plastic welding machines may fall to ¥100,000 ($13,808) or less in the future, attracting more users. As research deepens, especially into absorption rates between transparent and colored plastics and custom shaping, laser welding for plastics may see breakthroughs.

Focused on the Supporting Field of Laser Plastic Processing: TEYU S&A Chiller in the Spotlight

With rising demands for high-quality plastic welding across various industries, laser plastic welding technology is gaining popularity. The continued development of the laser plastic welding market also stimulates demand for laser accessory products, potentially leading to a surge in laser welding equipment adoption.

As an essential component of laser plastic welding equipment, cooling systems play a crucial role in temperature control. With 22 years of experience in laser cooling technology, Guangzhou Teyu Electromechanical Co., Ltd. (also known as TEYU S&A Chiller) has developed a range of industrial chillers suitable for most domestic and international brands of fiber laser, UV laser, CO2 laser equipment, and CNC machine tools. These chillers cover nearly all laser types and main power ranges, and they hold a strong market share in the plastic welding sector.

In this field, TEYU S&A industrial chillers are highly compatible with modern plastic laser welding equipment. For instance, TEYU S&A industrial chiller CW-5200 delivers precise temperature stability of ±0.3℃, operates on dual-frequency 220V 50/60Hz power, and supports both constant and intelligent temperature control modes. With features like stable cooling capacity, eco-friendly design, long service life, and high precision, it ensures that laser plastic welding machines maintain optimal operating temperatures.

As laser processing—particularly laser plastic welding—continues to grow in market applications and demand for higher power rises, industrial chillers will become an essential investment for many users.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.