Cracks in laser cladding are mainly caused by thermal stress, rapid cooling, and incompatible material properties. Preventive measures include optimizing process parameters, preheating, and selecting suitable powders. Water chiller failures can lead to overheating and increased residual stress, making reliable cooling essential for crack prevention.

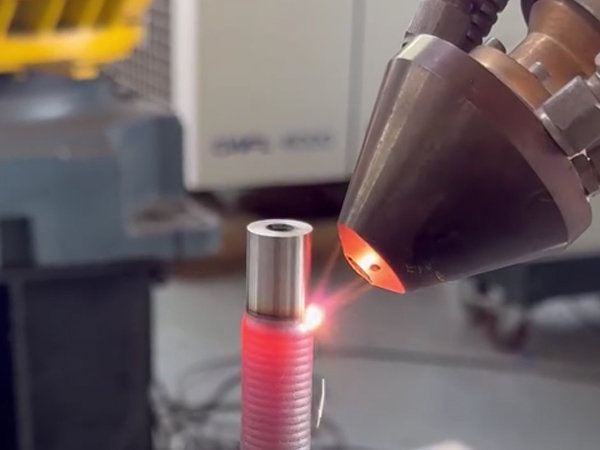

Crack formation is a common challenge in laser cladding processes, often affecting the quality and durability of the clad layer. Understanding the root causes and implementing effective preventive measures is crucial for achieving optimal results. Additionally, maintaining the proper function of a water chiller is essential, as cooling failures can significantly increase the risk of cracking.

Common Causes of Cracks in Laser Cladding

1. Thermal Stress: One of the primary causes of cracking is thermal stress resulting from a mismatch in the coefficient of thermal expansion (CTE) between the base material and the cladding layer. During cooling, stress concentrations develop at the interface, increasing the likelihood of cracks.

2. Rapid Cooling: If the cooling rate is too fast, residual stress within the material cannot be released effectively, leading to crack formation, particularly in high-hardness or brittle materials.

3. Material Properties: Crack risk increases when using substrates with high hardness (e.g., quenched or carburized/nitrided materials) or powders with excessively high hardness or poor compatibility. Substrates with fatigue layers or inconsistent surface quality can also contribute to cracking.

Preventive Measures

1. Optimizing Process Parameters: Carefully adjusting laser power, scanning speed, and powder feed rate helps regulate melt pool temperature and cooling rate, reducing thermal gradients and the risk of cracking.

2. Preheating and Controlled Cooling: Preheating the base material and applying slow, controlled cooling post-cladding can help relieve residual stress, lowering the potential for crack development.

3. Selecting the Right Powder Material: Choosing powders that match the base material in thermal expansion properties and hardness is essential. Avoiding extreme hardness or thermal incompatibility reduces internal stress and crack formation.

Impact of Chiller Failures on Crack Formation

A water chiller plays a critical role in the thermal management of laser cladding equipment. If the water chiller fails, it can lead to overheating of the laser source or key components, compromising process stability. Overheating may alter melt pool dynamics and significantly increase residual stress in the material, directly contributing to crack formation. Ensuring reliable chiller performance is therefore vital for maintaining cladding quality and preventing structural defects.

Conclusion

Cracks in laser cladding can be effectively minimized by managing thermal stress, selecting suitable materials, and maintaining stable cooling conditions. A reliable water chiller is an indispensable part of the system, helping to ensure consistent temperature control and long-term equipment reliability.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.