By managing sheet metal processing in-house, TEYU S&A Water Chiller Maker achieves refined control over the production process, increases production speed, lowers costs, and enhances market competitiveness, allowing us to better understand customer needs and provide more customized cooling solutions.

TEYU S&A Chiller is a professional water chiller maker with 22-year experience, providing high-quality chiller products for various industrial and laser applications. Our water chillers implement full-chain quality control from raw material procurement to finished product delivery through in-house sheet metal processing. This self-managed process ensures that every stage of chiller production meets the highest quality standards. The ability to autonomously control the production process not only guarantees the quality and consistency of sheet metal components but also highlights TEYU S&A’s expertise in water chiller manufacturing, ensuring top-tier product quality.

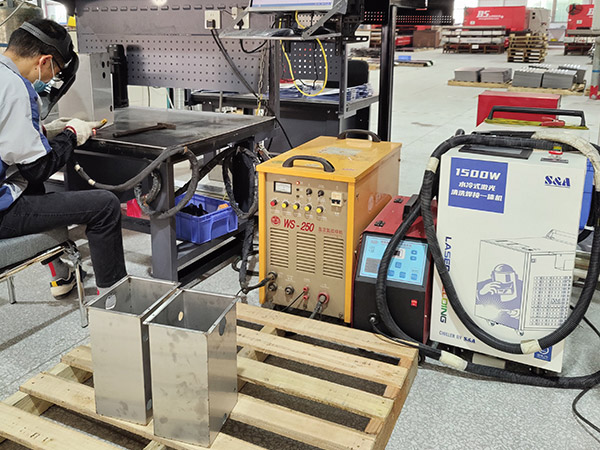

TEYU S&A Chiller has introduced advanced fiber laser cutting machines and handheld laser welding machines, combined with our self-developed water chillers for temperature control. This combination significantly enhances operational flexibility, cutting/welding precision, and efficiency, making it a powerful tool for sheet metal processing. Our integrated chiller machine, which supports the installation of fiber laser sources for laser welding, not only makes welding more flexible and convenient but also optimizes space utilization and reduces maintenance costs. This combination can easily handle complex welding tasks, effectively preventing overheating during the welding process. The convenience and efficiency of the chiller integration further elevate TEYU’s capabilities in sheet metal processing.

By managing sheet metal processing in-house, TEYU S&A Chiller achieves refined control over the production process. This approach optimizes production steps, reduces unnecessary intermediaries, increases production speed, lowers costs, and enhances market competitiveness. Furthermore, this in-house capability allows TEYU S&A Chiller to better understand customer needs, providing more personalized cooling solutions.

chiller CWFL-2000ANW for cooling laser welder

TEYU S&A uses self-developed chillers for cooling sheet metal processing

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.