TEYU fiber laser chiller CWFL-2000 is a high-performance refrigeration device. But in some cases during its operation, it may trigger the ultrahigh water temperature alarm. Today, we offer you a failure detection guideline to help you get to the root of the problem and deal with it quickly.

TEYU fiber laser chiller CWFL-2000 is a high-performance refrigeration device. But in some cases during its operation, it may trigger the ultrahigh water temperature alarm. Today, we offer you a failure detection guideline to help you get to the root of the problem and deal with it quickly. Troubleshooting steps after the E2 ultrahigh water temp alarm goes off:

1. First, turn on the laser chiller and ensure that it is in a normal cooling state.

When the fan starts, you can use your hand to feel the air blown out from the fan. If the fan doesn't start, you can touch the middle of the fan to feel the temperature. If there's no heat felt, it's possible that the fan has no input voltage. If there's heat but the fan isn't starting, it's possible that the fan is stuck.

2. If the water chiller blows out cold air, you need to remove the side sheet metal of the laser chiller to further diagnose the cooling system.

Then use your hand to touch the compressor's liquid storage tank to troubleshoot the issue. Under normal circumstances, you should be able to feel a regular slight vibration from the compressor. An unusually strong vibration indicates compressor failure or a blockage in the cooling system. If there's no vibration at all, further investigation is needed.

3. Touch the fry filter and capillary tube. Under normal conditions, both of them should feel warm.

If they are cold, proceed to the next step to check whether there is a blockage in the cooling system or refrigerant leakage.

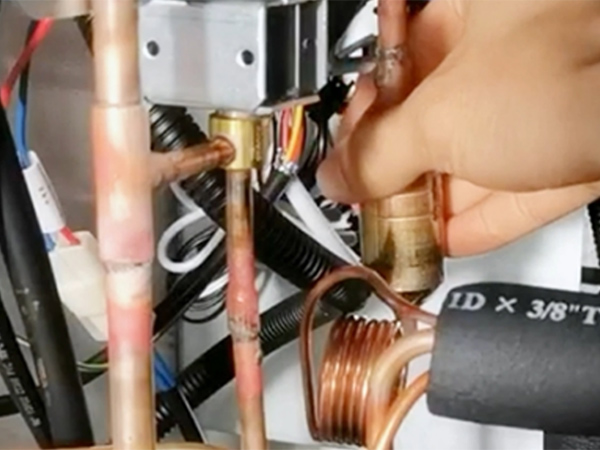

4. Gently open the insulation cotton and use your hand to touch the copper pipe at the entrance of the evaporator.

When the cooling process is functioning properly, the copper pipe at the entrance of the evaporator should feel cold to the touch. If it feels warm instead, it's time to investigate further by opening the electromagnetic valve. To do this, use an 8mm wrench to loosen the screws securing the electromagnetic valve, and then carefully remove the valve to observe any changes in the copper pipe's temperature. If the copper pipe quickly becomes cold again, it indicates a malfunction in the temperature controller. However, if the temperature remains unchanged, it suggests that the issue lies with the electromagnetic valve's core. In the event that frost accumulates on the copper pipe, it's a sign of a potential blockage in the cooling system or a refrigerant leak. If you notice any oil-like residue around the copper pipe, this points to a refrigerant leak. In such cases, it's advisable to seek assistance from skilled welders or consider sending the equipment back to the manufacturer for professional re-brazing of the cooling system.

Hopefully, you will find this guide helpful. If you want to know more about the chiller maintenance guide for industrial chillers, you can click on https://www.teyuchiller.com/temperature-controller-operation_nc8; If you can not resolve the failure, you can email [email protected] to contact our after-sales team for assistance.

We're here for you when you need us.

Please complete the form to contact us, and we'll be happy to help you.

Copyright © 2025 TEYU S&A Chiller - All Rights Reserved.