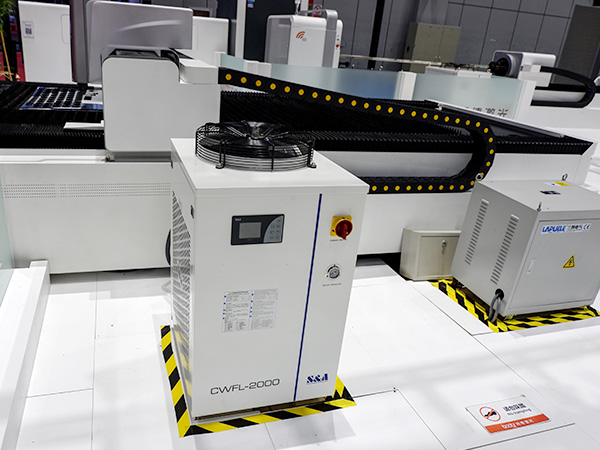

د فایبر لیزر پرې کولو ماشینونه او د CO2 لیزر پرې کولو ماشینونه دوه عام پرې کولو تجهیزات دي. پخوانی یې اکثره د فلزي پرې کولو لپاره کارول کیږي، او وروستی یې اکثره د غیر فلزي پرې کولو لپاره کارول کیږي. S&A فایبر لیزر چیلر کولی شي د فایبر لیزر پرې کولو ماشین یخ کړي، او S&A CO2 لیزر چیلر کولی شي د CO2 لیزر پرې کولو ماشین یخ کړي.

د فایبر لیزر پرې کولو ماشین او د CO2 لیزر پرې کولو ماشین ترمنځ توپیر چې د چیلر سره سمبال دی

د فایبر لیزر پرې کولو ماشینونه او د CO2 لیزر پرې کولو ماشینونه دوه عام پرې کولو تجهیزات دي. پخوانی اکثرا د فلزي پرې کولو لپاره کارول کیږي، او وروستی اکثرا د غیر فلزي پرې کولو لپاره کارول کیږي. د دې دوو پرې کولو ماشینونو د پرې کولو اصل او د لیزر چیلر انتخاب ترمنځ څه توپیر دی؟

د فایبر لیزر پرې کولو ماشین د رڼا سرچینې په توګه د فایبر لیزر کاروي. د لیزر لخوا د لوړ انرژۍ او لوړ کثافت لیزر بیم تولید د ورک پیس په سطحه متمرکز کیږي ترڅو هغه ساحه چې د ورک پیس په الټرا فائن فوکس ځای کې شعاع کیږي سمدلاسه منحل کیږي او بخار کیږي ترڅو ګړندي پرې کول ترلاسه کړي.

د CO2 لیزر پرې کولو ماشین د رڼا د خپریدو لپاره د کاربن ډای اکسایډ لیزر ټیوب کاروي ، د انعکاس کونکي د انعکاس له لارې رڼا د لیزر سر ته لیږدوي، او بیا د لیزر سر کې نصب شوي تمرکز کونکي عکس لخوا رڼا په یوه نقطه کې بدلوي. پدې وخت کې، تودوخه لوړې کچې ته رسیږي، کوم چې سمدلاسه د پرې کولو هدف ترلاسه کولو لپاره مواد د ګاز لپاره بدلوي.

د فایبر لیزر پرې کولو ماشینونه د CO2 لیزر پرې کولو ماشینونو په پرتله ډیرې ګټې لري. د فایبر لیزر پرې کولو ماشینونه د بیم کیفیت، د پرې کولو سرعت او د پرې کولو ثبات له مخې ګټې لري، د خدماتو ژوند اوږد دی او د کلیدي برخو د خدماتو ژوند 100,000 ساعتونو ته رسیدلی شي.

د لیزر پرې کولو دوه ډوله ماشینونه د پرې کولو میتودونو او پرې کولو موادو کې توپیر لري، او همدارنګه د لیزر چیلرونو په انتخاب کې چې دوی یخ کړي. د فایبر لیزر پرې کولو ماشین د لوړ رڼا تولید نرخ، د چټک پرې کولو سرعت او د فایبر لیزر ډیر تودوخې له امله د لوړ یخولو ظرفیت لرونکي چیلر ته اړتیا لري، کوم چې په ورته وخت کې د لیزر او پرې کولو سر دوه برخې یخ کوي. په هرصورت، د دې دوو برخو د تودوخې اړتیاوې توپیر لري، او لیزر د پرې کولو سر په پرتله ټیټ تودوخې ته اړتیا لري. S&A فایبر لیزر چیلر کولی شي دا غوښتنه په اسانۍ سره پوره کړي، د یو چیلر او دوه خپلواک یخچال سیسټمونو سره، د ټیټ تودوخې یخولو لیزرونو او د لوړې تودوخې یخولو پرې کولو سرونو سره، پرته له دې چې یو بل سره مداخله وکړي، او په همغږي ډول یخ شي. د CO2 لیزر پرې کولو ماشین کولی شي د عادي واحد گردش کونکي اوبو چیلر څخه کار واخلي ترڅو ډاډ ترلاسه کړي چې د یخولو ظرفیت د یخولو اړتیاو پوره کولو لپاره کافي دی، یا تاسو کولی شئ د دوه ګوني گردش کونکي اوبو چیلر غوره کړئ ترڅو د 2 CO2 لیزر پرې کولو ماشینونه په جلا توګه یخ کړئ ترڅو لګښتونه خوندي کړئ او د نصب کولو ځای کم کړئ. S&A CO2 لیزر چیلر هم پدې اړخونو کې ښه فعالیت کوي.

کله چې تاسو موږ ته اړتیا لرئ، موږ ستاسو لپاره دلته یو.

مهرباني وکړئ فورمه ډکه کړئ ترڅو موږ سره اړیکه ونیسئ، او موږ به خوشحاله شو چې ستاسو سره مرسته وکړو.