სამრეწველო გამაგრილებლების გაგრილების ეფექტზე მრავალი ფაქტორი მოქმედებს, მათ შორის კომპრესორი, აორთქლების კონდენსატორი, ტუმბოს სიმძლავრე, გაცივებული წყლის ტემპერატურა, ფილტრის ეკრანზე მტვრის დაგროვება და წყლის ცირკულაციის სისტემის დაბლოკვა.

ფაქტორები, რომლებიც გავლენას ახდენენ სამრეწველო წყლის გამაგრილებლების გაგრილების სიმძლავრეზე

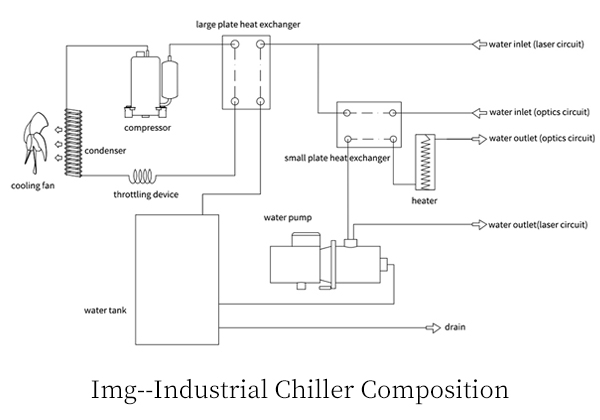

სამრეწველო გამაგრილებლების გაგრილების ეფექტზე მრავალი ფაქტორი მოქმედებს, მათ შორის კომპრესორი, აორთქლების კონდენსატორი, ტუმბოს სიმძლავრე, გაცივებული წყლის ტემპერატურა, ფილტრის ეკრანზე მტვრის დაგროვება და წყლის ცირკულაციის სისტემის დაბლოკვა. მოდით განვიხილოთ, თუ როგორ მოქმედებს ისინი გამაგრილებლის გაგრილებაზე:

1. გამაგრილებელი კომპრესორის გავლენა გაგრილების სიმძლავრეზე.

კომპრესორი სამრეწველო გამაგრილებელი მოწყობილობის მნიშვნელოვანი კომპონენტია, რომელიც გამაგრილებელი მოწყობილობის „გულის“ ტოლფასია. კომპრესორი მთავარი კომპონენტია, რომელიც მაცივარ აგენტზე მუშაობას ასრულებს. მისი გარდაქმნის სიჩქარე პირდაპირ გავლენას ახდენს გამომავალი გაგრილების სიმძლავრეზე იმავე შემავალი სიმძლავრის პირობებში და გამოცდილი მწარმოებლების კომპრესორები შედარებით ეფექტური და საიმედოა. S&A გამაგრილებელს აქვს ძირითადი კომპონენტების, როგორიცაა კომპრესორები, მკაცრი შესყიდვისა და ტესტირების პროცესი, რათა უზრუნველყოს, რომ თითოეული კომპონენტი აკმაყოფილებს გამოყენების სტანდარტებს.

2. გამაგრილებელი აორთქლების კონდენსატორის გავლენა გაგრილების სიმძლავრეზე.

თბოგადამცვლელის ზომა გამოითვლება კომპრესორის სიმძლავრის მიხედვით. თბოგაცვლის ეფექტურობის თვალსაზრისით: ფირფიტოვანი თბოგადამცვლელი > ხვეული თბოგადამცვლელი > გარსიანი და მილისებრი თბოგადამცვლელი; სპილენძს აქვს კარგი თბოგადაცემის ეფექტი, ამიტომ აორთქლებისა და კონდენსატორების უმეტესობა დამზადებულია სპილენძის მილებისგან. რაც უფრო დიდია თბოგაცვლის ფართობი, მით უკეთესია გაგრილების ეფექტი. თუმცა, აუცილებელია თითოეული კომპონენტის თანამშრომლობა, რათა შეესაბამებოდეს მთლიან გამაგრილებელს. S&A გამაგრილებელი ინჟინრების მიერ შექმნილი, იგივე სიმძლავრის S&A სამრეწველო გამაგრილებელი მოწყობილობას შეუძლია მაქსიმალური გაგრილების სიმძლავრის მიღწევა იმავე პირობებში.

3. ტუმბოს სიმძლავრის გავლენა.

ტუმბოს სიმძლავრის გავლენა სამრეწველო გამაგრილებელ მოწყობილობებზე ძირითადად სითბოს გაცვლის სიჩქარეზეა დამოკიდებული. ტემპერატურის სხვაობის შემცირება შესაძლებელია იმავე სითბოს გაცვლის ფართობის პირობებში. თუ სითბოს გაცვლის ფართობი არ არის საკმარისი, ტუმბოს ნაკადის გავლენა გაგრილების სიმძლავრეზე უფრო დიდი იქნება.

4. გაცივებული წყლის ტემპერატურის გავლენა გაგრილების სიმძლავრეზე.

აორთქლების სხვადასხვა ტემპერატურა გავლენას ახდენს სითბოს გაცვლის ეფექტურობაზე. რაც უფრო მაღალია ცირკულირების წყლის ტემპერატურა, მით უფრო დიდია გაგრილების სიმძლავრე, რომლის გენერირებაც გამაგრილებელს შეუძლია. ამიტომ, აღჭურვილობის სამუშაო ტემპერატურის დაკმაყოფილების წინაპირობიდან გამომდინარე, წყლის ტემპერატურა უნდა გაიზარდოს უფრო დიდი გაგრილების სიმძლავრის მისაღწევად.

5. ფილტრის გაჭედვის გავლენა.

გაჭედილი ფილტრი კონდენსატორზე მტვრის უფრო და უფრო მეტ დაგროვებას გამოიწვევს და გაგრილების ეფექტი სულ უფრო და უფრო გაუარესდება. ამიტომ, კარგი გაგრილების ეფექტის შესანარჩუნებლად მტვრის ფილტრი რეგულარულად უნდა გაიწმინდოს.

6. წყლის ცირკულაციის სისტემის ბლოკირების ეფექტი.

წყლის ცირკულაციის სისტემაში წარმოქმნილი ნადები ამცირებს გამაგრილებელი წყლის ნაკადს, რითაც გავლენას ახდენს გაგრილების სიმძლავრეზე. ამიტომ, ნადების შესამცირებლად და წყლის ნაკადის უზრუნველსაყოფად, გამაგრილებელმა რეგულარულად უნდა შეცვალოს ცირკულაციის წყალი (გამოხდილი ან სუფთა წყლის გამოყენებით), რათა შეამციროს ნადები და უზრუნველყოს წყლის ნაკადი, რათა გამაგრილებელმა შეინარჩუნოს კარგი გაგრილების ეფექტი.

S&A გამაგრილებლების მწარმოებელი კომპანია 20 წელია ავითარებს სამრეწველო წყლის გამაგრილებლებს და საფუძვლიანად შეისწავლა გამაგრილებლის ძირითადი კომპონენტები. შემუშავებულ სამრეწველო გამაგრილებლებს კარგი გაგრილების ეფექტი აქვთ მათი გამოყენების ინდუსტრიაში. 2-წლიანი გარანტიითა და დროული გაყიდვის შემდგომი მომსახურებით, S&A გამაგრილებლის წლიური მიწოდება 100 000 ერთეულზე მეტს შეადგენს, რაც მომხმარებლებისთვის კარგი და საიმედო არჩევანია.

ჩვენ აქ ვართ თქვენთვის, როცა დაგჭირდებით.

გთხოვთ, შეავსოთ ფორმა ჩვენთან დასაკავშირებლად და ჩვენ სიამოვნებით დაგეხმარებით.