A cikin masana'antar jirgin sama, ana buƙatar fasahar yankan Laser don bangarorin ruwa, garkuwar zafi mai ratsa jiki da tsarin fuselage, waɗanda ke buƙatar sarrafa zafin jiki ta hanyar injin injin Laser yayin da tsarin TEYU Laser chillers shine kyakkyawan zaɓi don tabbatar da daidaiton aiki da aiki.

Matsayin Fasahar Laser Wajen Kera Jiragen Sama | TEYU S&A Chiller

Yayin ziyarar shugaba Macron a kasar Sin, kamfanin samar da sufurin jiragen sama na China (CASC) da Airbus sun rattaba hannu kan wata muhimmiyar yarjejeniya ta siyan jiragen Airbus 160, da suka hada da jerin 150 A320 da jiragen A350 10, wanda darajarsu ta kai kusan dala biliyan 20. An danganta wannan nasarar da ci gaban fasahar Laser a cikin masana'antar kera jiragen sama na kasar Sin.

Aikace-aikacen Fasahar Laser a Masana'antar Jirgin Sama

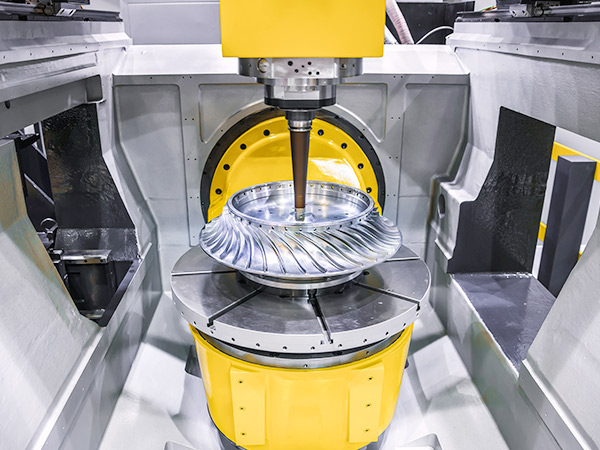

A cikin kera jirgin sama, ruwan wukake masu sifar fan sune mahimman abubuwan tsarin. Sun ƙunshi nau'ikan faranti daban-daban waɗanda dole ne a yi amfani da brazing mai zafi don samar da cikakkun tubalan masu siffa mai fan. Daga cikin wadannan faranti, ana samar da ruwan wukake ta hanyar birgima, yayin da sauran faranti suna buƙatar yankan Laser don sarrafa ramukan ruwa da biyan buƙatun taro.

Koyaya, tabbatar da daidaiton girma da matsayi, gami da saduwa da ƙayyadaddun ƙayyadaddun shimfidar wuri, yana gabatar da ƙalubale. Saboda haka, madaidaicin fasahar sarrafa laser yana da mahimmanci yayin aikin masana'antu. Wannan fasaha yana ba da garantin cika duk buƙatun sashi yayin da yake riƙe babban inganci da inganci.

Bugu da ƙari kuma, sarrafa filaye masu rufe fuska kuma yana buƙatar amfani da fasahar yankan Laser. Waɗannan abubuwan da aka gyara suna da sifar igiyar igiyar zobe da yawa, tare da ramuka daidai gwargwado zuwa saman, jere a adadi daga 2,000 zuwa 100,000. Irin waɗannan sassa galibi ana yin su ne ta amfani da ƙirar ƙarfe da walƙiya, kuma bayan maganin zafi, suna nuna nakasar saura mai wahala wacce ke da wahalar kawarwa. Saboda haka, wahalar sarrafa ramukan yana da mahimmanci, yana buƙatar amfani da hanyoyin yankan zobe na Laser.

Haka kuma, tsarin fuselage yana da buƙatu na musamman waɗanda ke buƙatar yankan Laser don sarrafawa. Idan aka kwatanta da hanyoyin sarrafa injina tare da cibiyoyin mashin ɗin CNC, yankan Laser yana ba da inganci mafi girma da kuma ikon sarrafa kayan ƙalubale kamar alloys titanium.

Fasahar Laser Yana Bukatar Kula da Zazzabi Ta Hanyar Laser Chiller Systems

Don cikakken yin amfani da babban aikin bugun Laser, yankan Laser, mashin ɗin laser, da sauran matakai, yana da mahimmanci don cire wuce haddi da zafi da aka haifar yayin aiki, hana abubuwa masu mahimmanci daga zafi fiye da kima, da magance matsalolin zafi waɗanda ke tasowa yayin injin Laser ta hanyar amfani da chillers .

Ingancin makamashi da Tsarin Cooling na Laser TEYU

TEYU ya ƙware a cikin tsarin sanyaya Laser na masana'antu na tsawon shekaru 21, yana ba da nau'ikan nau'ikan kayan sanyi na masana'anta tare da ikon sanyaya daga 600W zuwa 41kW. Wadannan chillers na masana'antu sun dace da masana'antun masana'antu da masana'antu sama da 100, suna tabbatar da kwanciyar hankali yayin yankan Laser, walƙiya Laser, alamar Laser, bugun Laser, mashin ɗin laser, da sauran fasahohin Laser daban-daban. TEYU Laser chillers suna ba da garantin aiki daidai da aiki, ingantattun hanyoyin sanyaya don tsarin sarrafa Laser ɗin ku.

Muna nan a gare ku lokacin da kuke buƙatar mu.

Da fatan za a cika fom ɗin don tuntuɓar mu, kuma za mu yi farin cikin taimaka muku.