![The wide applications of laser cutters suggest more opportunities for the manufacturing industry 1]()

Nowadays, laser cutters are having wider and wider applications and gradually replacing plasma cutter, waterjet cutting machine, flame cutting machine and CNC punch press because of high processing efficiency & precision, superior cutting surface quality and the ability to perform 3D cutting.

According to different laser generators, the current laser cutters in the market can be basically categorized into CO2 laser cutter, YAG laser cutter and fiber laser cutter.

Comparing with CO2 laser and YAG laser, fiber laser is more advantageous because of its high quality light beam, stable output power and easy maintenance.

As more and more metal is used in life and industrial application, the application of fiber laser cutter is becoming wider and wider. No matter whether it is metal processing, aerospace, electronics, home appliance, automobile, precision parts or gift items or kitchenware in our daily life, laser cutting technique is often applied. No matter it is stainless steel, carbon steel, aluminum, iron or other kinds of metals, laser cutter can always finish the cutting job very efficiently.

Fiber laser is relatively high-performance cutting laser for the time being and its life could be tens of thousands of hours. Running failure caused by itself is pretty rare unless it is human factor. Even working for a long time, fiber laser won't produce vibration or other bad effects. Comparing with CO2 laser whose reflector or resonator needs regular maintenance, fiber laser don't any of those, so it can save a huge maintenance cost.

Fiber laser cutting machine can adapt to the changing needs of productivity. The work piece doesn't need any further polishing, burr removing and other post-processing procedures. This has further saved labor cost and processing cost, which improved the production efficiency to a great extent. Besides, the overall energy consumption of fiber laser cutter is 3 to 5 times less than that of CO2 laser cutter, which increases the energy efficiency by 80%.

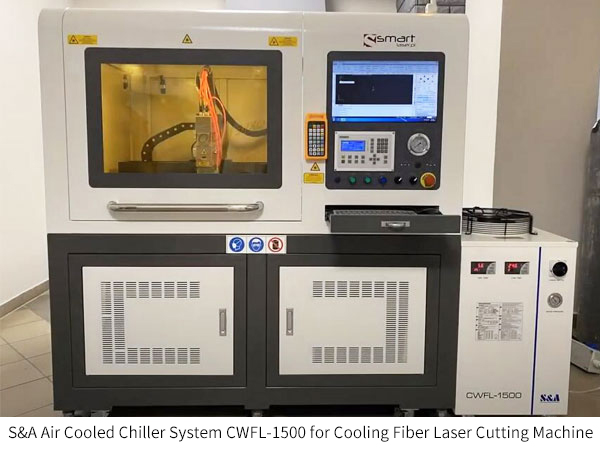

Well, to maintain the best running performance of the fiber laser cutter, the fiber laser must be well taken care of. To do that, the best way is to add an air cooled chiller system. S&A Teyu CWFL series air cooled chiller system is able to take away the heat from the fiber laser cutter by providing efficient cooling for the fiber laser and the laser head respectively, thanks to its dual temperature design. This CWFL series air cooled chiller system comes with high performance water pump so that stable water flow can be ongoing continuously. Some higher models even support Modbus485 communication protocol to realize communication between the laser system and the chiller.

Find out more about S&A Teyu CWFL series air cooled chiller system at https://www.teyuchiller.com/fiber-laser-chillers_c2

![air cooled chiller system air cooled chiller system]()